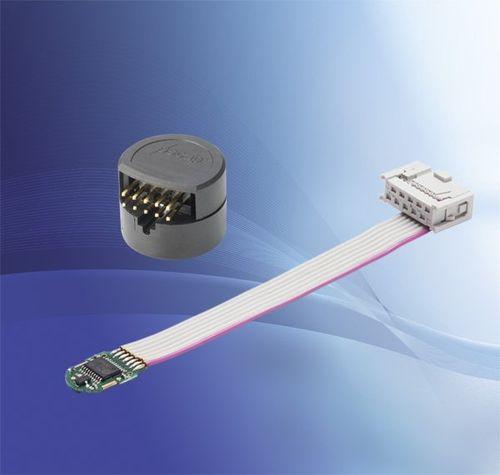

This product is easy, quick and precise in all aspects and is made of metal housing which reduces distortion. The main features includes a quick set up without having to align the transmitter and the receiver, easy sensitivity setting via potentiometer, light-on/dark-on mode via rotary switch and a fine, precise light beam.

The new ifm units which come with a robust metal housing can prevent distortion to a large extent as compared to the conventional plastic forks. The ifm units are less time consuming than the through sensors without the help of consuming alignment of transmitter and receiver.

These optical sensors are mostly used for part monitoring in feeder and handling systems. Additionally, the belt edge or double feed monitoring has the exact sensitivity setting via potentiometer which can prove to be very useful. The light beam along with a constant and small diameter is well-suited for monitoring shaft imbalance.

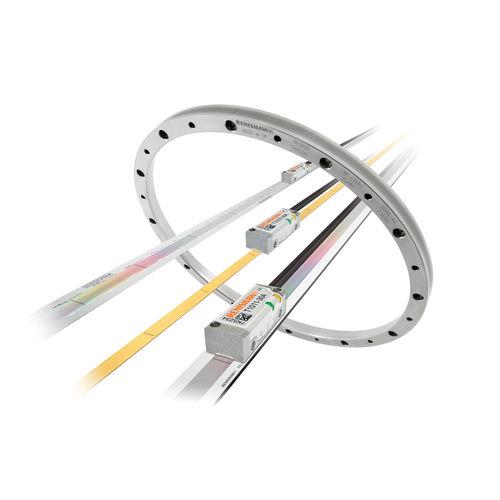

optical fork angle sensor

optical fork angle sensor