-

Technology:

piston

-

Lubrication:

lubricated

-

Product:

nitrogen, air

-

Cooling system:

cooled

-

Number of stages:

multi-stage

-

Flow:

Min.: 2060 l/min (544.19 us gal/min)

Max.: 6180 l/min (1632.58 us gal/min)

-

Pressure:

Min.: 25 bar (362.59 psi)

Max.: 90 bar (1305.34 psi)

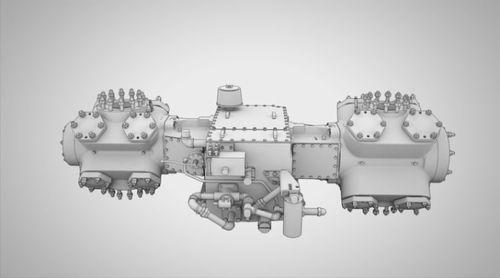

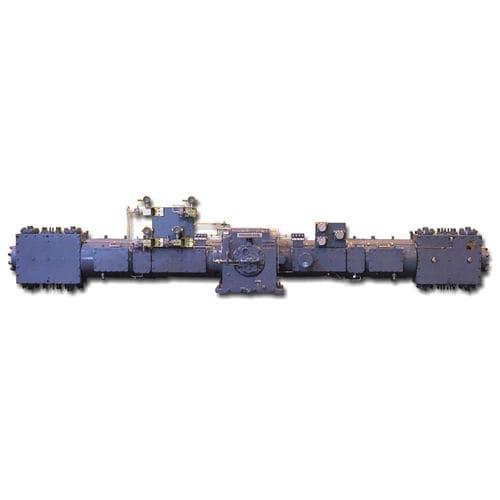

The GIB series: Air-cooled medium pressure booster compressors for the compression of air, nitrogen, helium and argon – for continuous operation in industrial applications

Fully automatic compressor control: B-CONTROL II

Optimum free air delivery rates for your application: For the compression of air, nitrogen, helium and argon

Compressor blocks in the BK 23 – BK 52 series: For uniform absorption of the internal gas forces

Low installation and maintenance costs: An important benefit of air-cooled systems

Powerful air cooling system: For compressor units with drive power ratings up to 110 kW

The air-cooled booster compressors in the GIB series by BAUER KOMPRESSOREN are characterised by their crankcase, which is pressure-resistant up to 16 bar.

A powerful air cooling system with generously dimensioned coolers combined with cylinders with extensive ribbing can be relied upon for best possible cooling of each individual compressor stage.

As cost-effective and durable system solutions for heavy-duty applications, these multi-stage boosters offer a wide and varied range of options: as a booster compressor of air from a compressed air supply system, as a nitrogen compressor of inert gases from generators or storage bundles, or as gas compressors for the compression of methane from pipelines or biogas directly from the treatment system.

cooled pressure booster / piston / lubricated / nitrogen

cooled pressure booster / piston / lubricated / nitrogen