The LTA100 is a patented system, designed to heat the compressed air of the spray gun .

Thanks to the high innovative content of the project and the technologies used to build the system, the LTA100 presents fundamental advantages over other traditional heating systems on the market:

The ability to keep the selected temperature constant, adjusting itself continuously without annoying temperature peaks or “on / off” effects produced by electrical resistance.

No problems with the length of the tube that feeds the spray gun. This technology heats only the last part of the hose.

The small size and its light weight allow an easy installation within any professional body shop.

WHY HEATING THE COMPRESSED AIR?

The air coming from the compressor is much colder than room temperature. It is also very inconsistent, making impossible to calibrate it properly for a professional painting job or other application systems.

Having a constant temperature allows you to have many practical advantages such as:

- Reduced energy usage: due to the fact that you don’t need to preheat the pieces to be painted

- Reduction of the defects on application and better distribution of the paint.

- Time saver. Reduces Cycle time.

- Slightly lower consumption of paint, varnish or base materials, thanks to better distribution and even coats

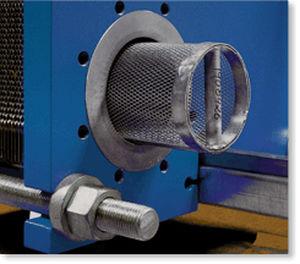

compressed air dryer

compressed air dryer