-

Applications:

powder

-

Type:

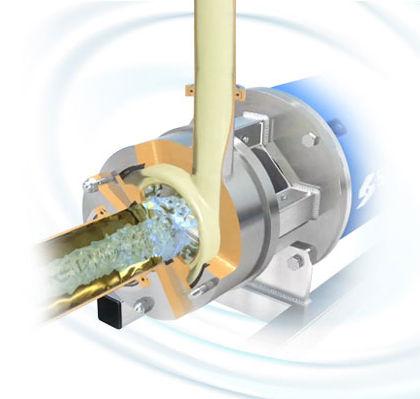

gravimetric, screw

-

Other characteristics:

automated

Special advantages:

Differential dosing scales principle

(Loss in weight) regulation

Precise online regulation and rapid correction in the event of target value deviations

Absolute weight acquisition

No falsification of readings due to apparent weight deviations and changing raw material properties

Weighing principle is not influenced by the material column in hopper

No intricate calibration is necessary

Maximum dosing accuracy also for low throughput rates

High grade dosing screws with linear dosing function

Preferred applications:

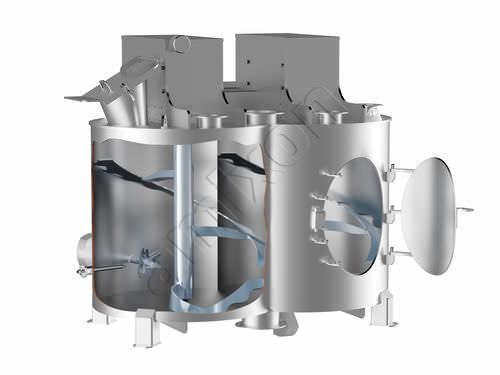

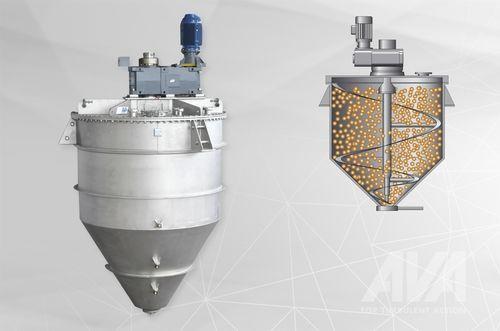

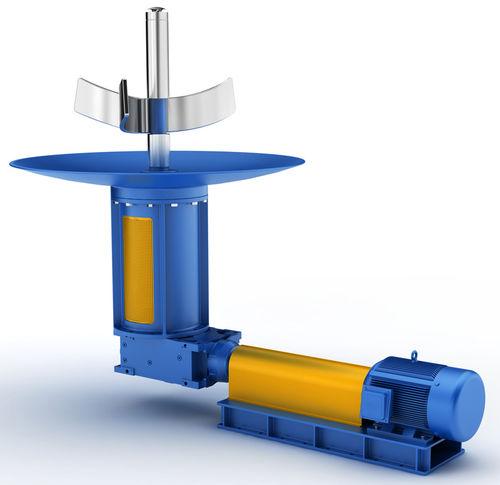

The new AZOGRAV® dosing system facilitates continuous, gravimetric supply of main and secondary components in extrusion and coextrusion processes. Complete extrusion facilities are effectively controlled by efficient, automated systems.

Tubular films

Flat film (chill roll)

Deep-drawn films and panels

Tubes/pipes and profiles

Spunbonded web

Synthetic thread

Functional principle:

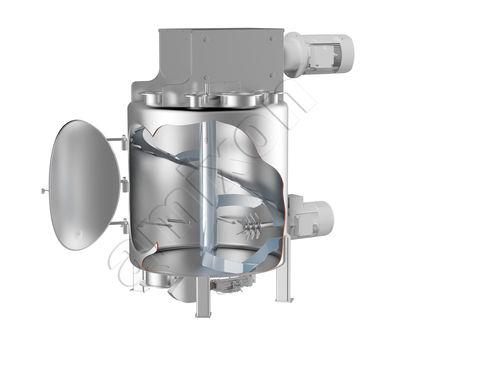

Vacuum conveying systems fill the weighing container for the main component and the storage containers for the secondary components through a material slide gate. The main component runs freely into the static mixing hopper while at the same time the differential dosing scales meter the secondary components into the mixing hopper. The optimum geometry of the mixing hopper ensures an extremely homogeneous mix is achieved during the material feed procedure. Any changes made to the target throughput values in the secondary components have a self-regulating effect on the throughput rate of the main component.

powder dosing unit / gravimetric / screw / automated

powder dosing unit / gravimetric / screw / automated