-

Type:

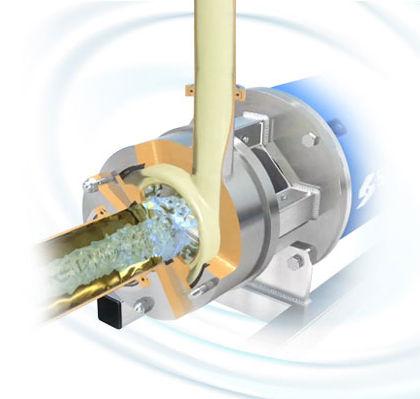

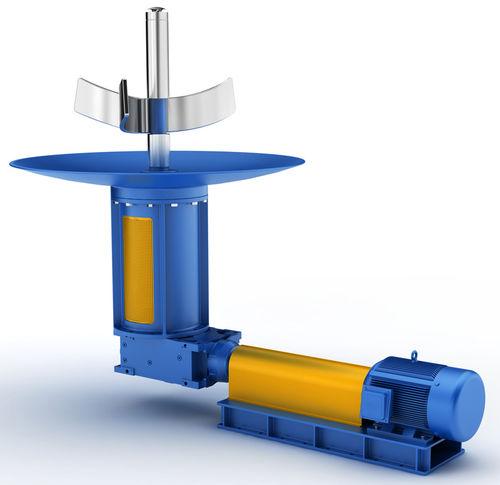

screw

-

Batch/continuous:

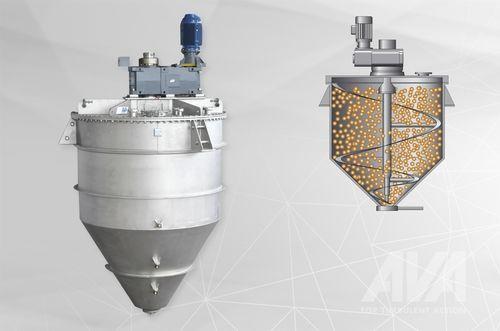

batch

-

Domain:

process

-

Other characteristics:

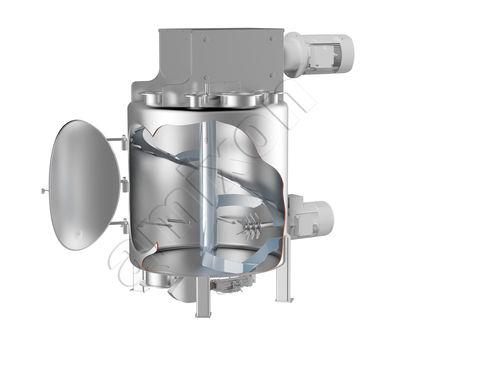

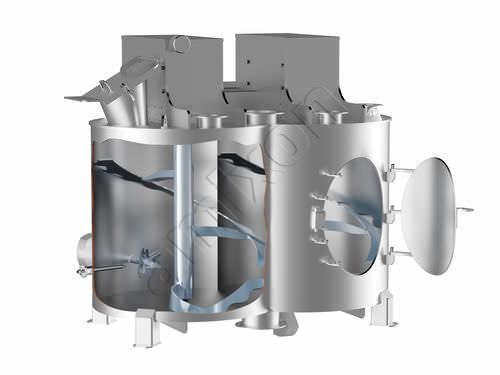

vertical, multi-axis, high-speed, for powders

-

Associated function:

with heat exchanger

Application

Effective process for the production of adhesives, sealants and other paste products from the low to high viscosity range.

Properties

A low-speed wall and bottom scraper feeds the other mixing devices continuously with the mixed product in a tangential direction and serves simultaneously in a stationary vessel as a discharge support. A separate screw ensures the vertical, large-volume mixing flow and a separate, high speed mixing shaft with one or more dissolver disks grants for the necessary dispersion power.

Options and Versions:

Variation of the machine head lift

Drive power according to product characteristics and batch size

Alternative rotation of the mixing shaft CW / CCW of the screw

Vacuum design with vacuum unit and vacuum control

One or two-armed wall scraper

Movable change vessels with and without double jacket / bottom

Integrated tempering system (Heating and/or cooling)

Whole machine on weighing cells for dosing purpose

Filler / powder feed below product level enabled by vacuum suction

FDA, GMP or SIL compliant design

Explosion protection according to ATEX 94/9/EG

Digital pressure, temperature, speed and/or electrical power measurement

Automatic speed reduction control

Oxygen or gas measurement monitoring systems

Flow and level measurement systems including control

Variable lift movement with height measurement

screw mixer / batch / process / vertical

screw mixer / batch / process / vertical