the food industry batch blender / for pasty products / for low-viscosity liquids / volumetric

the food industry batch blender / for pasty products / for low-viscosity liquids / volumetric

DOSELITE

INO Group

-

Applications:

for pasty products, for low-viscosity liquids

-

Type:

volumetric

-

Other characteristics:

high-precision, automatic, hopper

-

Domain:

for the food industry, for the chemical industry

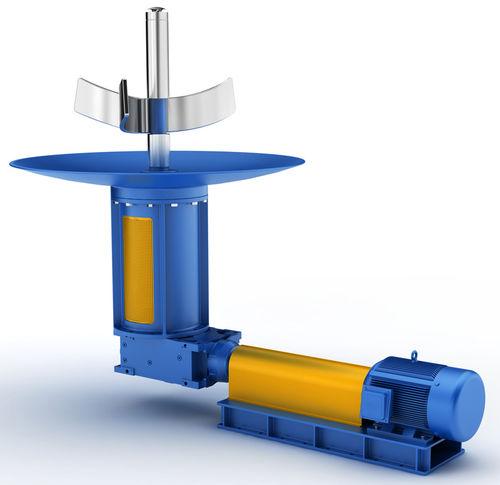

VOLUMETRIC PNEUMATIC DOSING MACHINE 50 LITERS HEATED HOPPER WITH MIXER

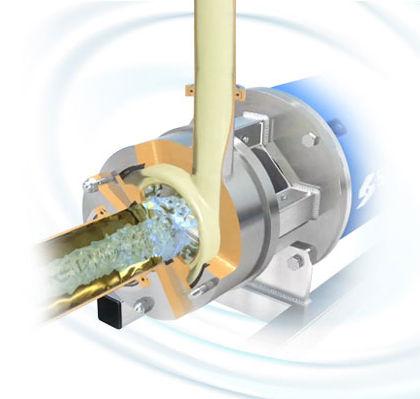

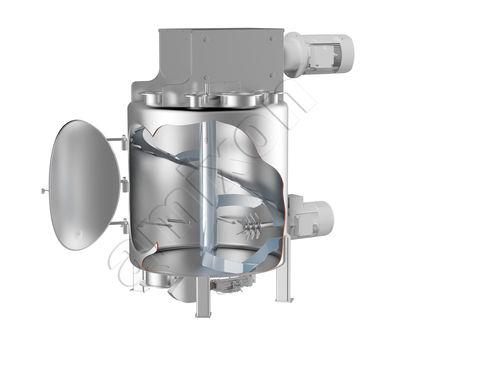

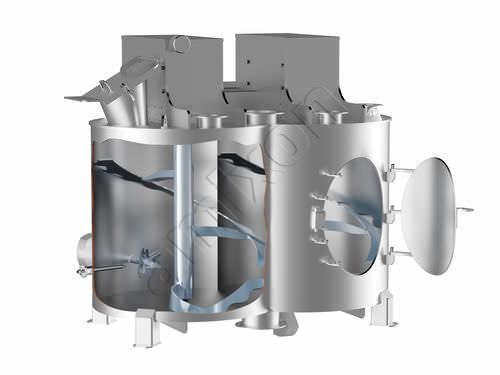

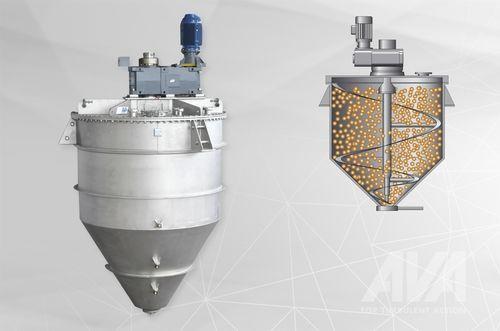

The system is composed by a 50 litres s/steel cylindrical hopper with conical bottom. Double jacket execution; internal part AISI 316 made; external part AISI 304 made. Heating system composed by 2 x 1500 W resistances, diathermic oil, PT100 temperature feeler, thermostat. Electrical motor with mechanical speed reducer. Manhole on the cover for loading and tri-clamp connection. Pneumatic volumetric dosing machine with table top frame with 20-

680 ml range. The volumetric chamber is heated by a MICA insulated electrical resistance, controlled by a thermostat. Three ways DN25 rotary valve, connected at the hopper exit, performs the product suction / output operation. Suction and output speed can both be adjusted through the selectors. The machine can be started with a

pedal (included) or can work in automatic mode. This function is particularly advisable for performing the first part cleaning operation with hot water. Every part that goes in contact with the product can be dismounted by hand. The machine is CE and food grade certified

Our fillers have been designed, built and put on the market to dose any kind of product of the following sectors: alimentary, chemical, cosmetic and pharmaceutical. Through a suction system the product is introduced into the dosing chamber. As it has reached the quantity required, the piston begins to push the product on the outside

through the output valve and the related nozzle. Different kinds of valves can be installed on the machine according to the product to be managed.

On the rear side of the dosing machine there is a hand-wheel that determines the product volume.