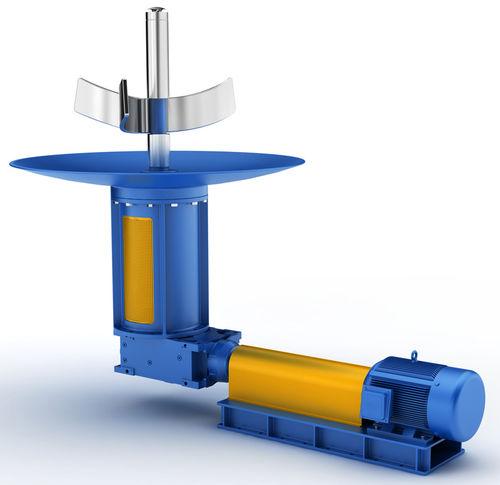

adhesives dispenser / fluid / for high-viscosity media / for paint

adhesives dispenser / fluid / for high-viscosity media / for paint

4RD6-EC

INO Group

-

Applications:

for adhesives, fluid, for high-viscosity media, for paint, for shear-sensitive media, resin, brazing paste, for pasty products, for chemicals, for chlorine, silicone

-

Type:

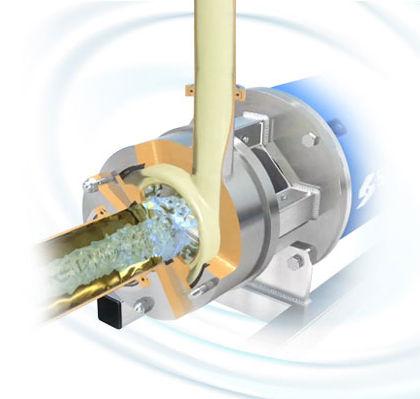

volumetric, screw

-

Other characteristics:

automatic, single-component, continuous, high-precision, manual, semi-automatic, low-capacity, programmable

-

Domain:

laboratory, for the electronics industry

The compact ViscoTec Dispenser 4RD6-EC ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

Absolutely precise, consistent and reliable dosing of a wide variety of materials - thanks to the special rotor-stator geometry. Alternately opening chambers allow the gentle transfer and pulsation-free dispensing of product.

Your advantages:

- non-stick coated interior

- reverse-flow possible (no dripping or stringing of product)

- linear relation between drive speed and dosing volume

- constant dosing volume, also with density or viscsity fluctuations

- reliable dosing even without heating the material

- long lifetime due to a range of components for specific material

- time and cost saving maintenance and cleaning

- quick assembly

- as dosing system with ViscoPro drive: easy programming of quantity and speed (see separate data sheet)

Application:

- dot application or bead dosing, variable quantities possible

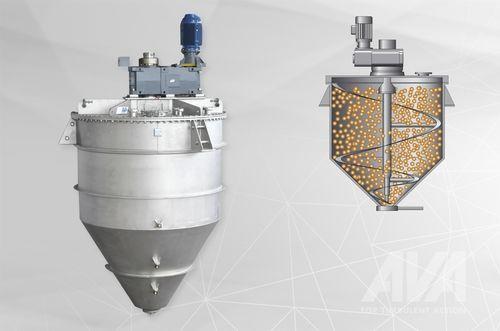

- dosing of all low and high viscosity adhesives and sealants

- particularly suitable for abrasive, high-filled or shear sensitive material

Technical data:

- dosing volume: ~ 0.12 ml/rev.

- min. dosing quantity: 0.005 ml*

- operating temperature: +10° to +80°C *

- material temperature: -20° to +80°C *

- max. speed: 125 upm *

- max. permissible torque: 8 Nm

- max. dosing pressure: 30 bar*

- max. supply (input) pressure: 20 bar*

- weight: approx. 900 g

* depends on material