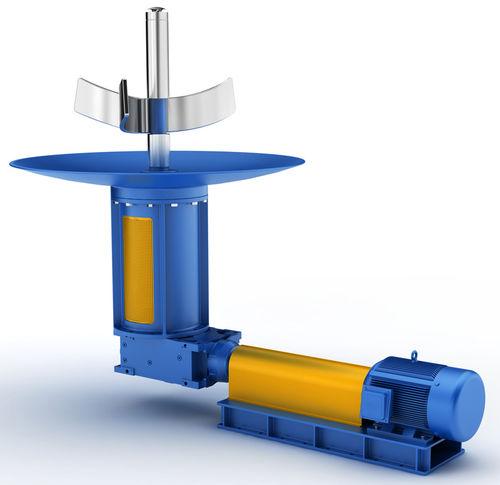

mixer impeller / anchor type / helical ribbon / 4-blade

mixer impeller / anchor type / helical ribbon / 4-blade

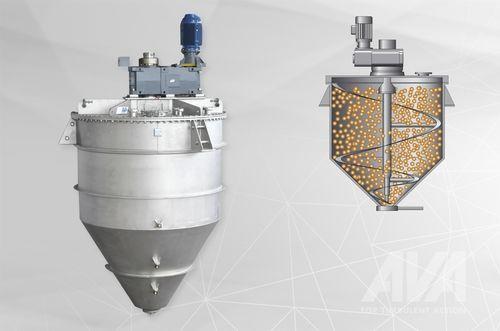

max. 1 000 000 Cp

INO Group

-

Applications:

mixer

-

Configuration:

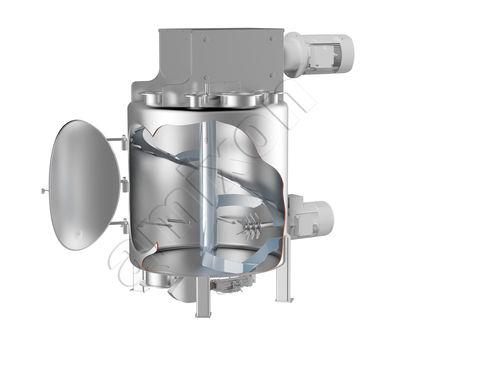

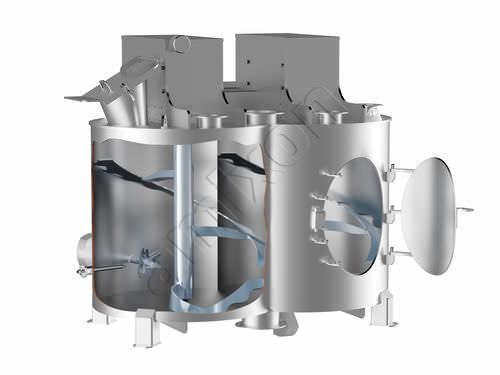

anchor type, helical ribbon, 4-blade, 3-blade

-

Flow:

radial-flow, axial-flow

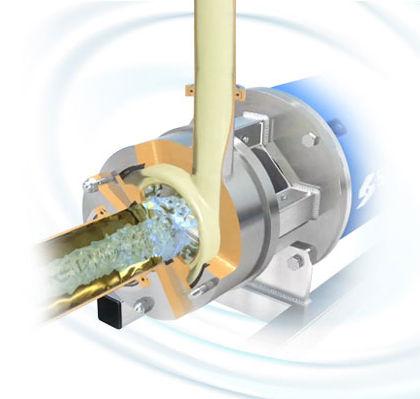

The complexity of the problems concerning the mixing technology requires careful consideration of the process requirements in order to identify the suitable agitator to solve these issues. Shaft and impellers are the most important components that need to be carefully designed to achieve the process requirements. The shaft is an essential and critical mechanical element for the performance of the mixer because if it is not rigidly supported, it may vibrate and cause misalignment and consequently damage to the whole system. Zucchetti, with the experience acquired in 50 years of activity and the continuous monitoring of all essential mixing improvements, guarantees the highest operating procedure on quality and design through the analysis of torsional / bending stresses and the critical speed, in order to meet all mechanical requirements and avoid any unpleasant breakdown. Understanding of key parameters and the effect created by the different impellers on flows may suggest the best solution to produce the desired result. More efficient impellers mean greater benefits in pumping and power efficiency with cost-effective mixing technology. Zucchetti is constantly engaged on the research and development of new impeller designs that can provide opportunities for process improvements. We focus our attention on applications where advanced impeller design and cutting edge mixing solutions are required in order to comply with all critical situations that can interest the process.