CNC cutting tool grinding machine / 4-axis / high-precision

CNC cutting tool grinding machine / 4-axis / high-precision

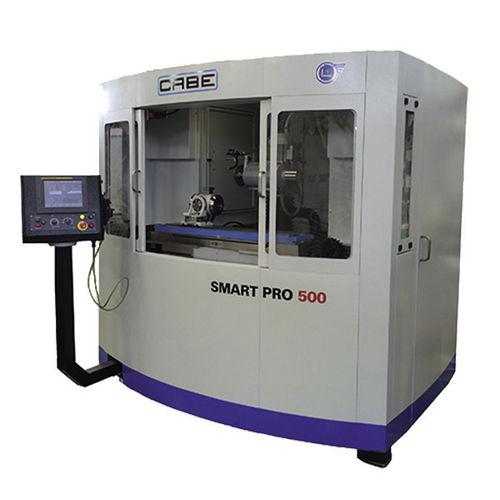

SMART 500

INO Group

-

Control type:

CNC

-

Number of axes:

4-axis

-

Other characteristics:

high-precision

-

X travel:

Min.: 0 mm

Max.: 500 mm

-

Y travel:

Min.: 0 mm

Max.: 230 mm

-

Z travel:

Min.: 0 mm

Max.: 270 mm

-

Spindle speed:

Min.: 2000 rpm (12566.37 rad.min-1)

Max.: 7000 rpm (43982.3 rad.min-1)

-

Distance between centers:

Min.: 0 mm

Max.: 680 mm

INNOVATIVE AND PRECISE

The SMART 500 CNC model, with its many variants, is the outcome of the continuous technological research, that has made Cabe a leader in its industry. To obtain design targets, volute friction guides have been installed on the longitudinal axis (worktable) and transverse axis (head carriage), with the dual benefit of smoother travel combined with increased working load. The wheel centre spindle has a wide range of speeds, thus allowing accurate calibration for the best cutting result.

The machines is available in two configurations. Smart 500 and Smart Pro 500. The SMART PRO 500 model has a simultaneous movement of the CN axes for the grinding of tools and pieces with complex geometric shapes like cylindrical spiral or conical spiral.

PROCESSING TYPOLOGIES

• Cylindrical mills: cutting angle and first and second dorsal rake angle of both axial and radial cutting edges.

• Taper mills: cutting angle and first and secondo dorsal rake angle on both axial and radial cutting edges.

• Three edge mills: dorsal rake angle.

• Taps: mating angle.

• Countersink tool: angle on curced surface.

• Given the extreme precision of the machines, it is possible to grind flat surfaces, cylindrical holes and small part shafts.

ADVANTAGES

Intuitive:

• Fanuc control with intuitive and customised user interface.

• Easy installation.

• Safe and simple use.

Tailor-made:

• Customisation of the software and the mechanical parts.

• Machine designed to suit specific cutting requests.

Reliable:

• Reduced wear of the components.

• Quality guaranteed by years of experience and research.

• Long machine life.