high-pressure reactor / catalyst / batch / laboratory

high-pressure reactor / catalyst / batch / laboratory

sk3000 Kneader Reactor

INO Group

-

Type:

high-pressure, catalyst, batch

-

Laboratory/process:

laboratory

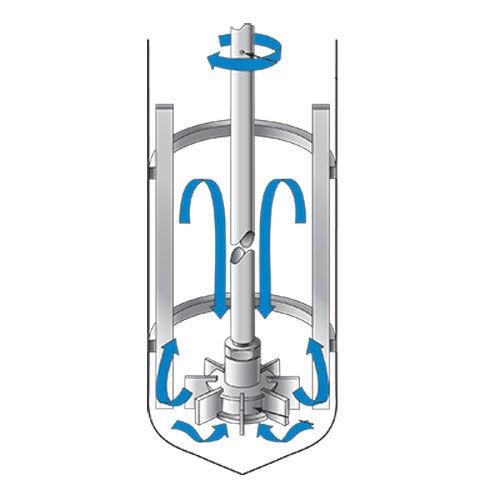

The stirred (batch) reactor is used to create a slurry using powdered catalyst in homogeneous catalyst research. Agitation creates isothermal conditions and allows the researcher to select the reaction time. Select the Dispersi-max impeller for circulating the head space gas into the liquid phase. Other impeller shapes are offered to simulate other processes.

FEATURES

- Reactants:

Liquid/Solids, Gas/Liquid/Solids, Vapor/Liquid/Solids

- Typical Reactions:

Liquefaction, isomerization, polymerization, hydrogenation, oxidation, hydro-treating, catalyst testing.

- Standard Reactor Volume:

1.83 in.3 (30 cm3) to 244 in.3 (4,000 cm3)

- Common Customizations:

Special materials, windows (video camera view ports and/or spectro-scopic windows), non-standard capacity, non-standard vessel diameter

and length, MagneDrive® with higher torque rating, welded heattransfer jacket for high pressure/temperature heat transfer fluid system, complete intrinsically safe barrier, control system, and special vessel lift mechanism. ASME code stamp, CE mark for Pressure Equipment Directive, and CRN.

- Standard Material:

316 Stainless Steel and HASTELLOY® C-276

- Standard Agitator Speed

1,000 to 3,300 RPM

Maximum Allowable Working Pressure/Temperature Combinations:

See "Product Literature" above for Design specifications.