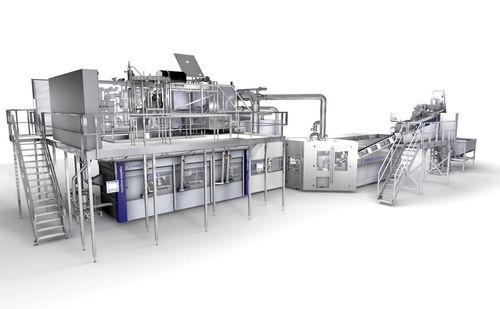

automatic top load case packer / cardboard box / case erector

automatic top load case packer / cardboard box / case erector

SD series

INO Group

Technical characteristics

Case packing solution designed with completely modular mechanical and control system architecture

Various product handling systems possible depending on the speed and the product, with the choice of sequential (stop & go) or continuous technology

Compact and positive vertical case forming system

Sealing of top flaps (using glue or adhesive tape) with case squaring guaranteed

Solution equipped with 16 servo-motors in total, including 6 for the forming operation and 3 for the sealing operation

Cantilever structure for walk-in access into the heart of the machine

Advantages

Case magazine at an ergonomic level of 900mm to facilitate reloading by the operator

Multi-case loading (from 1 to 4 most frequently) to reduce the loading speed and consequently limit hazards during the critical phases of product gripping, transfer and loading into the packaging

Precise and smooth product gripping: optional integration of the Cermex AN gantry packer and ER20 Pick & Place arm, or any third party polyarticulated robot

Structure with completely independent subassemblies to facilitate machine operation and maintenance

Ergonomic Human/Machine Interface with an input menu per module

Performance

Automation and control architecture developed in compliance with the OMAC standard (OMAC (Organization for Machine Automation and Control)

Payload: from 20kg to 160kg (products and tooling)

Speed: up to 40 cases per minute depending on the product characteristics

2 versions available: small size range for cosmetic bottles and large size range for detergent bottles