-

Container type:

multi-container, for plastic bottles, can

-

Operational mode:

stand-alone

-

Type:

weight, rotary, multi-head, monobloc

-

Product applications:

for viscous liquids, for pasty products, fruit juice, dairy products, for edible oil, margarine

-

Other characteristics:

net weight

-

Throughput:

Min.: 3000 p/h

Max.: 43000 p/h

A simple principle: one weight, one measurement. Weight filling is the perfect solution for low conductive product.

This filling technology is based on the principle of net weight filling. The microprocessor programs the electronic scale based on the bottle weight and activates the fill process.

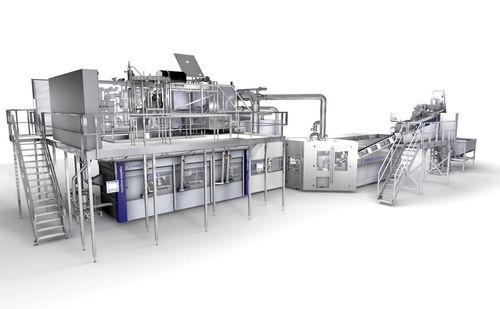

3 configurations are available: stand-alone filler, a monobloc with 2 or 3 turrets including rinsing, heat sealing and/or capping, and the Combi version with a Sidel blower. The filler can also be synchronized with other machines (air conveyor, CIP station, etc.).

An innovative capping system for snap-on caps places the caps on the container directly from the outfeed starwheel, which reduces the space required for lines with lower output rates.

weight filler / multi-container / for plastic bottles / can

weight filler / multi-container / for plastic bottles / can