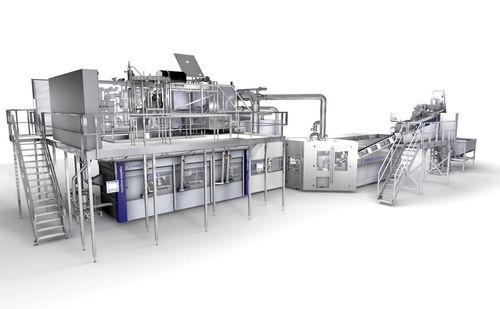

The glass industry must increasingly deal with special bottle shapes. The demands on the flexibility of the cold end rise again. More and more necessary functions, always differentiated handling requires more and more space in the halls of the glass producers and cause serious space problems. MSK has developed a bottle turning system which is characterized by an extremely compact size.

MSK has developed a bottle alignment station, which is characterized by an extremely compact size. A real feature: The MSK bottle alignment station is "mobile" on a mobile rack. It can be docked laterally at a bottling line without the line must be built before apart mechanically.

Easy operation of the system control

A central connector system makes the connection to the line control very quickly and easily. The MSK Emsy (visualization and operator terminal) recognizes the MSK bottle turning system through the active connection. The operator has to activate it in the line control and can simply transfer via the touch panel the bottle parameters of the bottling line to the bottle alignment station. A manual input and configuration is not necessary.

bottle positioner

bottle positioner