-

Product applications:

tray

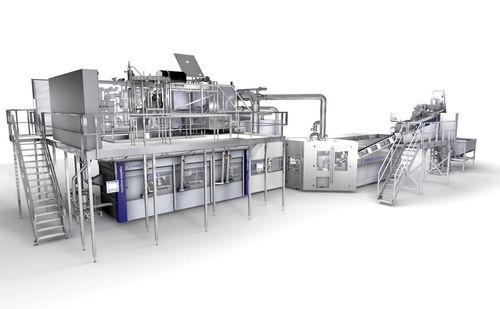

The NEW TS (Tray Stacker) stacks on two or more layers clusters of plastic, metal or glass containers both clustered in cardboard trays or pad and loose (this latter solution solely for fit-in type cans). This device can be installed on SK shrinkwrappers, on WP casepackers and on CM combined packers.

It consists of an electronic stacking device operating in continuous motion, which achieves an output rate up to 60 packs per minute according to the machine model and to the product handled.

Pack collations can vary according to the container shape, capacity and size; in general, the most requested collations are: 4x3 and 6x4. It is available both for single and for double lane production.

Operation

After coming out of the trayformer, two or more packs are stacked by means of a Cartesian coordinate system.

Before the pack enters the shrinking tunnel, the film is wrapped around the products and overlapped at the base of the pack.

tray stacker

tray stacker