-

Other characteristics:

automatic

Fagor Arrasate has designed, manufactured, assembled and installed at their destination automatic and flexible lines or systems for the manufacture of:

U shaped units or cabinets.

Side panels with folded ends.

Refrigerator tops with clinched bends and flaps.

All kind of doors (welded at the four corners, with brackets in corners, open at upper and lower ends, with large radii and curves allowing panoramic forms, etc.)

Various parts, such as motor compressor supports, central and lower reinforcements, etc.

The processes for these lines start with cold-rolled or pre-painted metal blanks or coils and often end with the complete manufactured part, with all its elements, ready to be mounted on the assembly lines, for example: the refrigerator body with the tanks assembled, the front and lower reinforcements riveted, etc.

The hourly production rates which have been achieved are in general for very high production ranges with flexible and frequent changes of model, the most significant of these being the following:

190 cabinets per hour, totally assembled.

300 pre-painted metal panoramic doors per hour.

220 4-corner plasma-welded doors per hour

200 sets of right/left panels per hour.

The changes of model, apart from a few exceptions, are automatic, using servos with numerical control (CNC) or electronic cards with encoders and PLC. With these systems, record model change times have been achieved, and line and system availability has been improved, obtaining up to 90% availability.

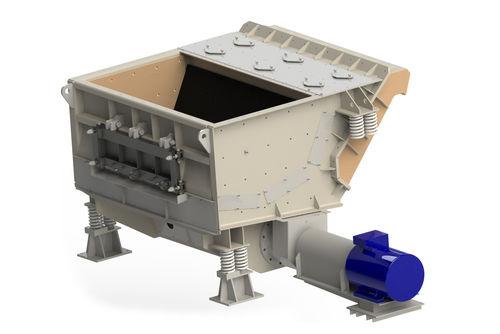

automatic production line

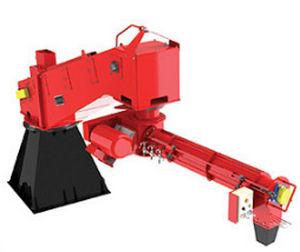

automatic production line