-

Operation:

hydraulic

-

Function:

hardening

-

Other characteristics:

hot, with automatic feeder

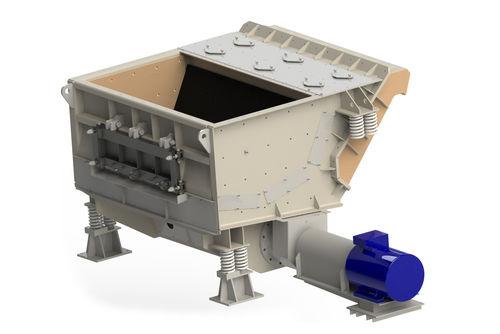

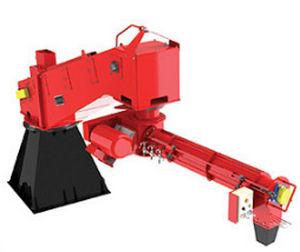

Press hardening or hot forming are the processes of making metal enabling the making of high strength parts by a quick hardening of boron steels heated over 900 degrees of temperature. A common hot forming line includes a furnace, a hydraulic press or servo press, a blank destacking device, as well as other surrounding components that assure the Process control (artificial vision, temperature, and so on) and automation. Fagor Arrasate makes and designes press hardening installation with mordern automation systems based on high speed feeders and/or robots to result in a flawless synchronization with the press and facilitating integration with different concepts of furnacing, all of which is depending on the requirement of data about available site, speed, and parts to be manufactured. Furthermore, the close co-operation between die-maker BATZ and Fagor Arraste delivers to the customers the possibility of having turn key solutions to make A pillars, B pillars, front panels, or any other high strength parts.

hydraulic press / hardening / hot / with automatic feeder

hydraulic press / hardening / hot / with automatic feeder