-

Options:

laser

The laser perforationg system JENOPTIK-VOTAN® A Classic manufactures integrated predetermined breaking points in airbag covers by means of the laser. The laser creates a line of weakness along the required airbag flap contour by stringing together blind holes from the material base side. A specially designed sensor technology prevent the material to be totally penetrated by the laser always in a way that a minimum residual wall thickness is always preserved. Thereby and by the perforation line the material is weakened in a way that the airbag tears open at exactly this point in the even the airbag is activated.

With the laser perforationg system JENOPTIKVOTAN® A you are using an industrially proven process for the non-contact and wear-free making of predetermined breaking points.

Scope of Application

Laser perforation of defined lines of pre-weakening :

- in car instrument panels for passenger and knee airbags

- for airbag covers in door trims and passenger modules

- for interior trim parts with integrated side and thorax airbags

- in steering wheel caps for driver airbags

- in textile or leather decoration and compound materials

Miscellaneous

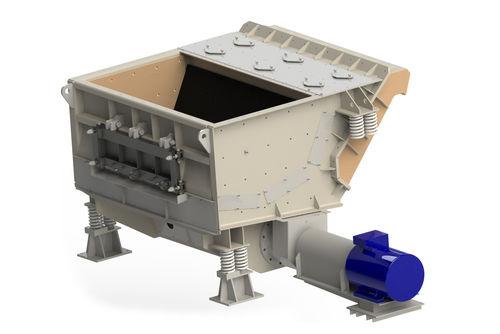

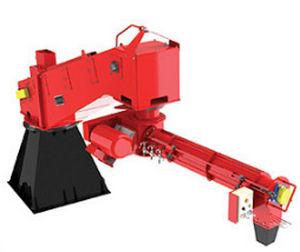

The laser perforating system JENOPTIK-VOTAN® A Classic offers a maximum of flexibility and a lot of optional process extensions for individual requirements. There is a selection of user-specific installation layouts and various equipment options including rotary tables and belt conveyors. Processing of PVC-containing materials is possible as well as additional edge or functional trimming. The JENOPTIK-VOTAN® A Classic is ideal for special requirements or highest demands in flexibility and quality.

laser perforating machine

laser perforating machine