-

Options:

vacuum

Discovered in 1791, titanium has entered into the interest of OROTIG S.r.l. since its beginning, late 1980s. At that time, the use of titanium in the medical sector has become significantly diffused thanks to its excellent biocompatibility and to special mechanical properties. As a matter of fact, joints, attachment plates for fractures, encapsulations for biological and intra-osseous implants for dental rehabilitation, have been started to be produced by means of OROTIG-patented technology for casting titanium.

Such a technology implies the presence of a reduced-in-size single chamber, hard vacuumed to avoid the presence of oxidizing air elements. where the metal is melted by the electric arc in presence of Argon-gas. When the casting takes place, the melting/casting camber’s box tilts rapidly and the molten metals are pushed down into the flask by a controlled Argon-gas overpressure. All this make possible to obtain very compact, oxidation-free casting extremely accurate in details and quite precise and fitting even in very diminutive sections.

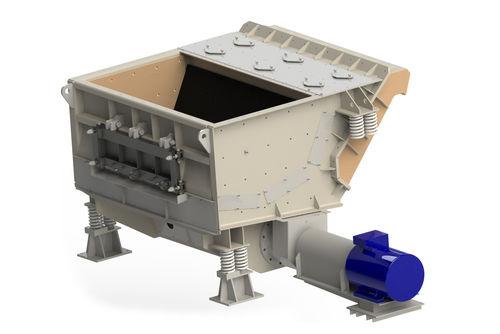

vacuum casting machine

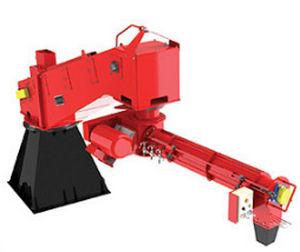

vacuum casting machine