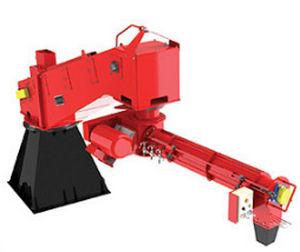

multi-material rapid manufacturing machine / for complex parts

multi-material rapid manufacturing machine / for complex parts

AM250

INO Group

-

Printed material:

multi-material

-

Applications:

for complex parts

-

X travel:

250 mm

-

Y travel:

250 mm

-

Z travel:

300 mm

The Renishaw AM250 comprises of a vacuum chamber evacuation as well as high purity argon gas that produces a high grade atmosphere. This is essential when oxygen content must be reduced including building in reactive materials such as titanium. Gas consumption is reduced through the utilization of sealed and welded chamber. The AM250 has an external powder hopper with valve interlocks to enable integrating components when in operation. The hopper can be removed easily for maintenance or to change with a secondary hopper utilizing a universal lift. Moreover, the powder overflow tanks are located outside the chamber, allowing unused materials to be sieved and reintroduced to the process through the hopper while the system is operating. This unit is designed particularly for the manufacturing industry, featuring simple functionality while fulfilling demands.