-

Type:

process

-

Function:

cleaning

-

Orientation:

vertical

-

Rotational speed:

3000 rpm (18849.56 rad.min-1)

This technologies utilized for treating process liquids like coolants, sludge from painting operations and other industrial liquids must not only guarantee an excellent cleaning effect but they must also be economical. With its sturdy and sophisticated centrifuge technology Rösler offers a wide range of cleaning solutions which include not only numerous technical features but also excel with their outstanding cost efficiency. The powerful centrifugal filters from Rösler, available with 2- or 3-phase separation, are usable for a wide range of different cleaning tasks and can easily be adapted to specific applications.

Cleaning of different kinds of process liquids:

Machining centers: Maintenance of coolant and grinding oil reservoirs

Technical ceramics: Cutting, grinding and polishing

Glass processing: For technical and decorative purposes, etc.

Wafers for solar applications: Cutting, grinding

Paint booths: Maintenance of the water reservoir in wet paint applications

ECM (electro-chemical deburring): Maintenance of the water and electrolyte balance

High pressure water jet blasting: Aerospace applications

Recycling of precious materials: Gold, silver, copper, etc.

Wet paint applications: De-watering of the paint sludge

General sludge de-watering: Reduction of residual water content

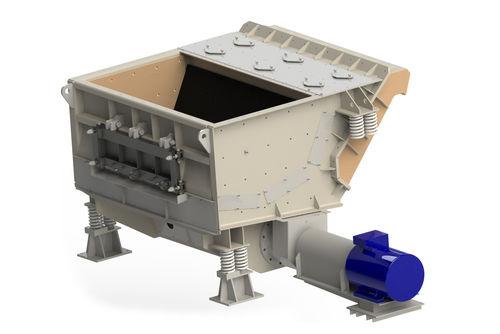

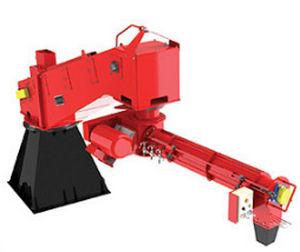

process centrifuge / cleaning / vertical

process centrifuge / cleaning / vertical