-

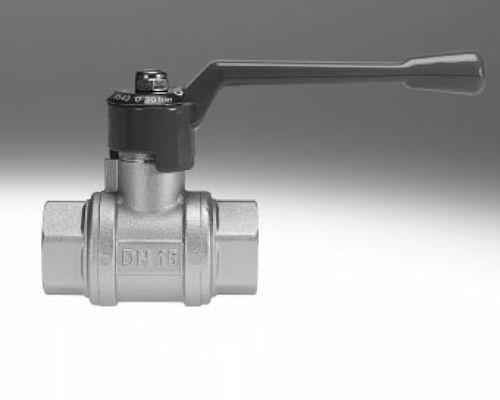

Type:

ball

-

Operation:

manual

-

Function:

mixing, dispensing

-

Body:

stainless steel

2200-545 Series 2-Component No-Drip Valve

The 2200-545 Series automatic mix/dispense valves ensure precise, efficient and cost-effective operation, making them tough to beat for pourable materials. These valves provide complete control over the application of metered twocomponent adhesives or sealants – either automatically or manually. They are one of the best point-of-application dispense valves available today.

The short stroke length and double-air operation of the valve combine produces an immediate start or stop to the dispense cycle, making it extremely responsive and ideal for automated applications.

Its durable design – including wear-resistant seals and hardened components – enhance the valve’s service life. This provides a distinct advantage for high-volume, repetitive operations or when using filled or abrasive materials.

The unrestrictive internal design allows for the free flow of even high viscosity materials, while insuring that the two material components remain separate until they enter the No-Flush™ mixer/nozzle.

Features and Benefits

2200-545 Series No-Drip Dual-Ball and Seats for low

viscosity, pourable materials

Point-of-application mix and dispense valve assembly

No-Flush disposable static mixers reduce waste and

minimize maintenance

Readily mounted with two drill-thrus and fixtured/

positioned using two alignment holes

Double air operated (air to open / air to close) ensures

immediate start and stop

Multiple model options provide added versatility:

For wide ratio materials

Stainless steel wetted components

Handles for manual operations

ball valve / manual / mixing / dispensing

ball valve / manual / mixing / dispensing