-

Type:

butterfly

-

Operation:

pneumatic

-

Function:

regulating

-

Media:

for gas

-

Temperature:

300 °C (572 °F)

-

Operating pressure:

25 bar (362.59 psi)

-

DN:

Min.: 300 mm

Max.: 3000 mm

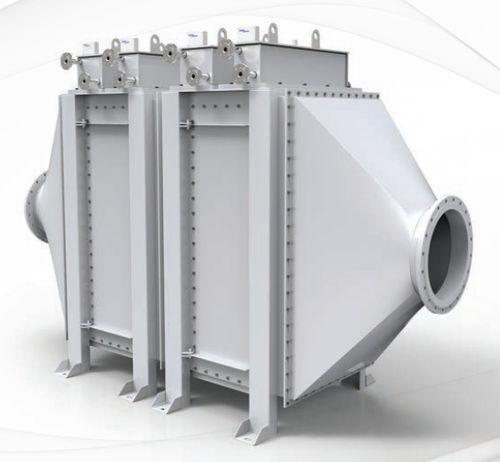

Being part of the proven KÜHME high-performance valve series for industrial applications, the PKIII type is used in any application where safe and quick shut-off of gaseous media is required. The electro-pneumatically controlled quick-closing butterfly flap valve sets standards for tightness, service life and reliability even in the most demanding applications. The butterfly flpa valve is mainly used as a tight shut-off device for gaseous media in systems with low pressures.

Media: gaseous

Application: Power plant technology, Steelworks, Biogas & Landfill gas,

Industrial combustion, Air separation plants PSA

Application areas

- Automatic shut-off valves for gaseous fuels, designed as steering arm flap in double

seat design with EC-type-Examination (Module B) in acc. with PED (until DN 1300)

- Main shut-off for gas systems

- Pipe systems for gaseous media in all industrial sectors

Nominal size: DN 300 to 3000

Operating pressure: max. 2.5 bar g,

from DN 800 upwards: 1.0 bar g (static)

Differential pressure for operation: up to 200 mbar

Operating temperature: max. + 300°C

Advantages

- Closing time < 3 seconds

- Safety guaranteed by the proven sealing system with soft seal (leakage rate A in acc. with EN 12266-1)

- Closing of the valve is dampened to reduce pressure surges in the pipeline

- Double seat - one valve instead of two separate valves - compact and cost-efficient

solution

- Convenient automatic testing of the sealing system during plant operation - without

having to dismantle the valve

- Heavy duty design for high amount of operating cycles

- High-performance valve with a long service life

butterfly valve / pneumatic / regulating / for gas

butterfly valve / pneumatic / regulating / for gas