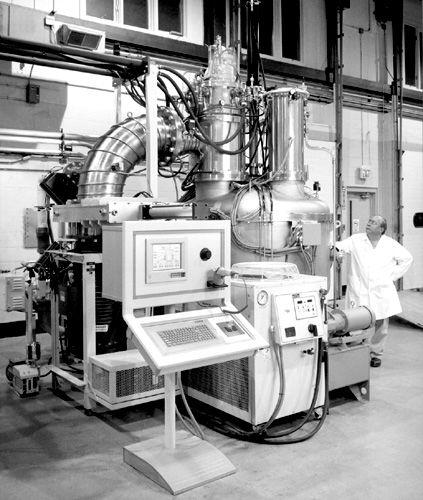

diffusion furnace / brazing / sintering / annealing

diffusion furnace / brazing / sintering / annealing

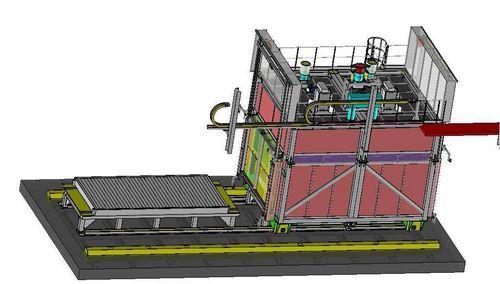

Four Station Indexing Sintering Furnace

INO Group

-

Function:

brazing, sintering, annealing, heat treatment, oxidation

-

Configuration:

chamber, top-loading

-

Heat source:

electric

-

Atmosphere:

forced convection, inert gas, high-vacuum, controlled atmosphere, vacuum

-

Other characteristics:

for the ceramic industry, for the electronics industry, laboratory, for aeronautical applications, for metalluregy, for precious metals, for non-ferrous metals

-

Maximum temperature:

Min.: 0 °C (32 °F)

Max.: 2300 °C (4172 °F)

General Specifications:

- Five chamber design to process 4 loads simultaneously

- Separate loading, heating, cooling and oxidation chamber

- Hot zone Size 12” dia. x 22” high (305mm dia. x 559mm high)

- Tantalum, Tungsten heating zone (other materials available)

- 2300°C max.

- +/- 10°C temperature gradient across usable zone

- High capacity Diffusion pumping system 10" or 16"

- Gas heat exchanger for rapid load cooling

- Our highest throughput batch sintering furnace

- Fully automated cycles with computer interface