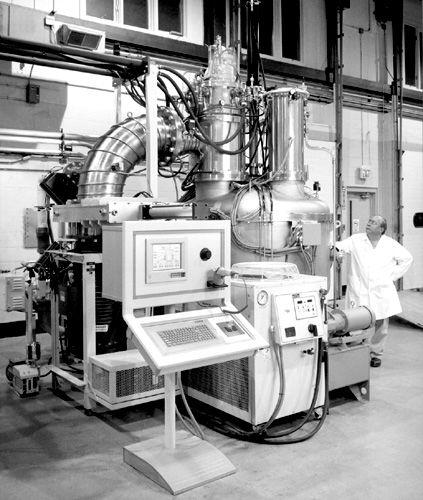

medium-size furnace / heat treatment / annealing / sintering

medium-size furnace / heat treatment / annealing / sintering

Medium sized heat treat furnace

INO Group

-

Function:

heat treatment, annealing, sintering, melting, hardening, brazing, nitriding, oxidation

-

Configuration:

bell

-

Heat source:

electric

-

Atmosphere:

vacuum, controlled atmosphere, inert gas, hydrogen

-

Other characteristics:

horizontal, laboratory, for the ceramic industry, for metalluregy, for aeronautical applications, for precious metals, for non-ferrous metals, medium-size

-

Product applications:

for production, powder

-

Maximum temperature:

Min.: 0 °C (32 °F)

Max.: 2200 °C (3992 °F)

Our popular mid-sized heat treating furnace contains a 1 cubic foot usable zone capable of temperatures up to 2200C and can be equipped with many options. The unit shown here features a turbo system and our HMI computer interface package. Other options we have provided on this heat treat furnace include operation in Hydrogen, diffusion and cryo pumping systems, heat exchanger for rapid cooling in gas, pyrometer, etc. In other words, we will customize our furnaces to your specific needs. The hot zone features tungsten rod or mesh heating elements, insuring excellent uniformity and longivity. This furnace comes equipped with an intuitive and easy to use computer interface, allowing fully automated runs. In addition it provides data trends and storage ( Data acquisition), display and logging of alarms, unlimited recipe profiles temperature control, security, configuration settings, etc. The PC is an industrial flat panel PC mounted in the control console and is built to withstand harsh environments. The furnace can be used for both R&D or as a batch furnace for production.