press furnace / holding / for sample digestion / heat treatment

press furnace / holding / for sample digestion / heat treatment

Series PT

INO Group

-

Function:

press, holding, for sample digestion, heat treatment

-

Configuration:

chamber, cabinet

-

Heat source:

electric

-

Atmosphere:

vacuum, controlled atmosphere, multi-gas

-

Other characteristics:

laboratory, for metalluregy, for non-ferrous metals, for aeronautical applications, for carbon fiber

-

Product applications:

for parts, for small parts

-

Maximum temperature:

Min.: 0 °C (32 °F)

Max.: 2300 °C (4172 °F)

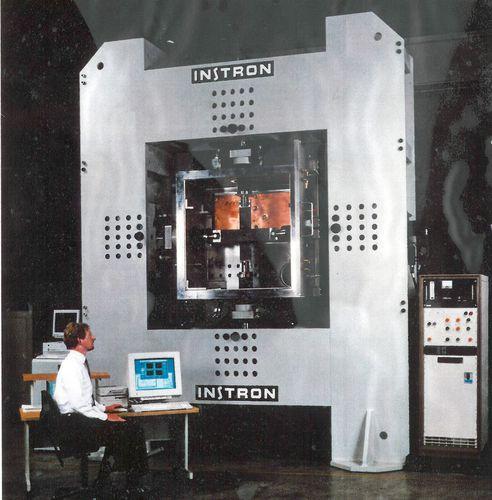

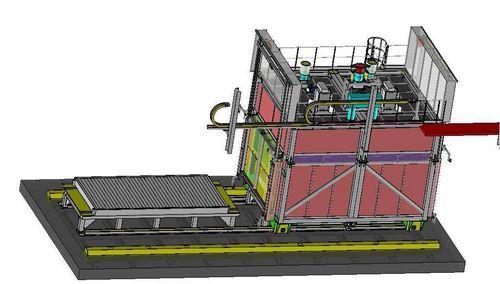

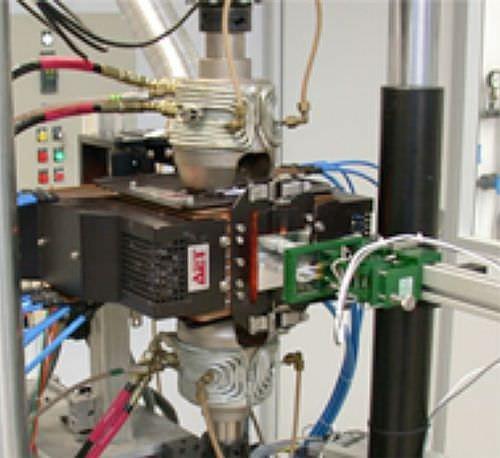

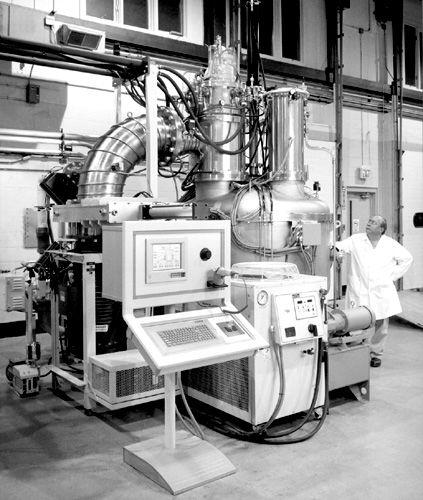

MRF supplies furnace systems to mount in different manufacturers test frames allowing a combination of temperature, environmental and physical test conditions that no single manufacturer offers by themselves. Bringing together our areas of expertise, the physical test furnaces allow samples to be tested for compression strength, tensile strength, torsional strength, deflection, fatigue, multi-axial testing, etc. under various temperature and atmospheres. The chamber accommodates test grips, extensometers and other test equipment via the various ports and feed throughs. Our hot chambers allows samples to be heated anywhere from room temperature to 2300°C max. (4172F).

Specifications:

Temperatures up to 2300°C (4172F).

Chambers designs to mount in virtually any test frame.

All necessary ports and feed throughs to accommodate physical test equipment

Metallic, Ceramic or Graphite Hot Zones.

Uniform +/-10C temperature zones

Various hot zone sizes available to match sample sizes

Rough or high-vacuum systems.

Gas systems: inert, oxidizing or reducing.

Double-walled, water-cooled stainless steel chamber.

Complete turn-key system

Furnace can double as a batch furnace