-

Options:

inkjet

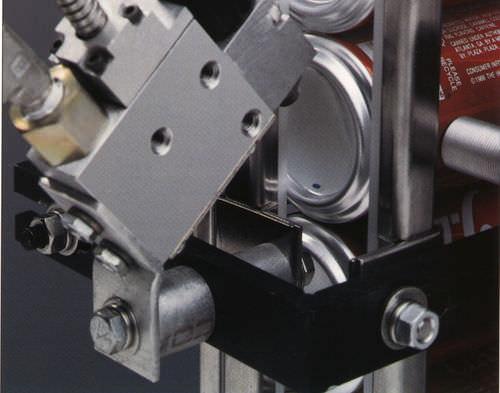

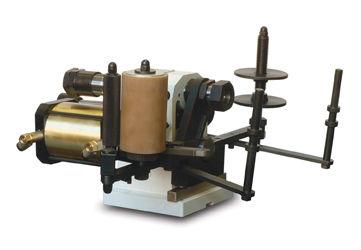

Nordson® Ink-Dot I.D. system is useful for identifying which spray machine has coated each can on the assembly line. A small dot of ink is applied on each can's bottom by the system as it gets into the spray machine. The system is perfect for two- and three-piece container operations with aluminum and steel cans.

Every machine on the coating line features a distinct ink color, which leads to a quick identification of the source of improper coatings. This eliminates the difficulty of shutting down all machines on the line for ascertaining the defect-producing machine.

With the Ink-Dot I.D. system, valve module can be replaced without removing the manifold. It is possible to perform enamel-rater and metal exposure tests on actual production cans. The system is configurable for the application of thermal-sensitive inks to the exterior of two- and three-piece food cans.

Labor costs incurred on recurrent testing are reduced thanks to the quicker and improved processes. Colored and UV inks can be easily applied.

inkjet identification system

inkjet identification system