fluidized bed dryer / hot air / granulator / cooler

fluidized bed dryer / hot air / granulator / cooler

BATCH OR CONTINUOUS FLUID BED DRYER

INO Group

-

Drying method:

fluidized bed, hot air

-

Associated function:

granulator, cooler

-

Applications:

for the processing industry, for bulk materials, for the chemical industry, for pharmaceutical industry, for the food industry

-

Other characteristics:

modular, batch, horizontal, vertical, continuous

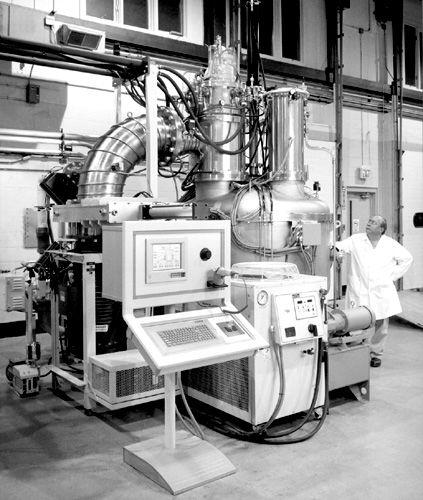

FLUID BED DRYER “CIRCULAR BATCH TYPE”

The most common of the Fluid Bed Dryers, it works batch wise and has its process chamber integrated into the main body. Incorporated bag filters and cyclones are employed to reduce the dispersion of fine powders during the process.

Fully automatic operation of material feed, drying (cooling) and product discharge can be easily performed by this equipment.

Special detachable process chamber is also available on request.

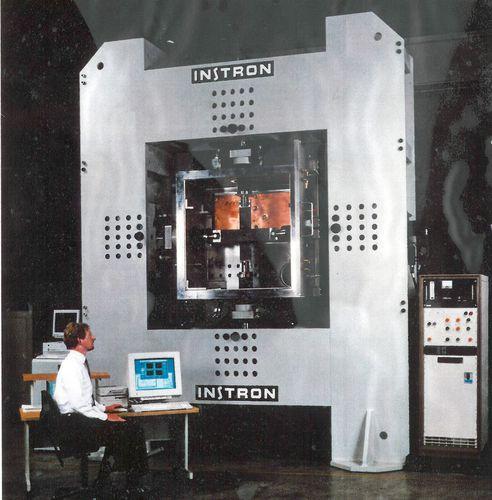

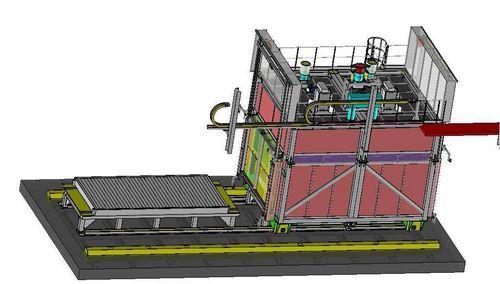

FLUID BED DRYER “HORIZONTAL CONTINUOUS TYPE”

This particular type has a rectangular process chamber where the material is continuously supplied from the inlet port of the chamber and then dried while it moves horizontally to the outlet port where the processed material will be discharged.

The process chamber is designed with different stages allowing different process in the same operation. The most common example is: Feed the wet product, rough dry it, finish dry it, cool it down and then discharge it.

Incorporated bag filters, separated bag filters and cyclones are employed to reduce the dispersion of fine powders during the process.

The continuous operation increases productivity, minimize production costs and maintain consistent product quality resulting in the right equipment for mass production operation.