-

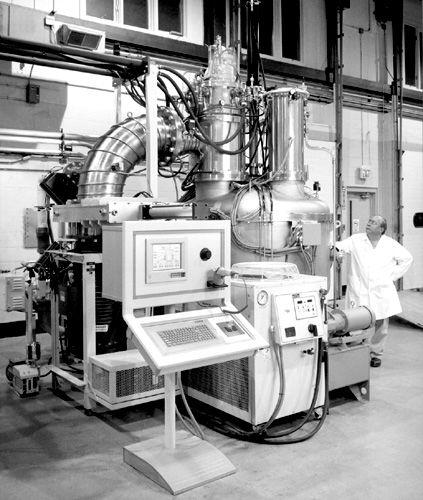

Function:

melting

-

Configuration:

bell

-

Heat source:

induction

-

Atmosphere:

inert gas

-

Other characteristics:

for metalluregy

-

Maximum temperature:

1600 °C (2912 °F)

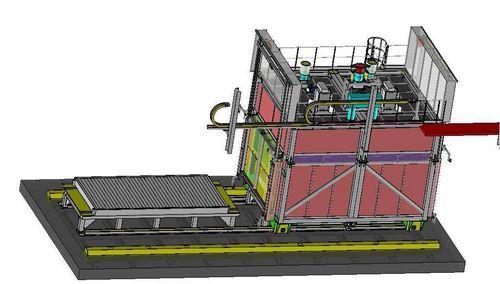

TMA is a family of powder atomization plants designed to produce metal powders, working with a new revolutionary double chamber concept for a better flow consistency and control.

They are based on an induction furnace working under protective atmosphere in a chamber where molten metal is poured and hit by a jet of high pressure water or inert gas.

Induction heating ensures a good homogenization of the melt thanks to the action of mixing of the magnetic field during the melting of the metal in the crucible.

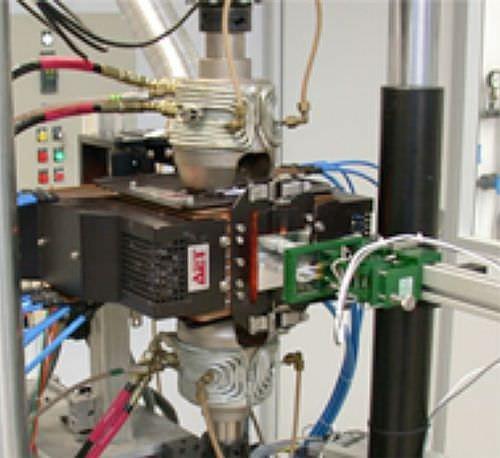

Following the step of melting and homogenization, metal is poured vertically through an injection system positioned on the lower base of the crucible (nozzle).

The equipment is designed using a revolutionary dual-chamber conception that provides numerous advantages compared to the traditional gravity casting system: the melting chamber and the process chamber are completely independent and, at the time of casting, the injection system controls the metal flow through the nozzle by controlling the pressure difference between the two chambers.

This leads to an improved flow control respect to the simple gravity pouring and consequently ensures a more uniform size of the powders, reducing the distribution sigma.

Streams of high pressure water or inert gas is aimed and directed towards the metal beam in order to ensure a fast solidification in the form of fine powder.

The system can be operated manually or fully automatic thanks to the programmability of parameters, the monitoring system based on the PC for the acquisition of the variables and parameters of the process, for a graphical editing interface, and RS232 connections and Ethernet to the corporate network.

melting furnace / induction / inert gas / for metalluregy

melting furnace / induction / inert gas / for metalluregy