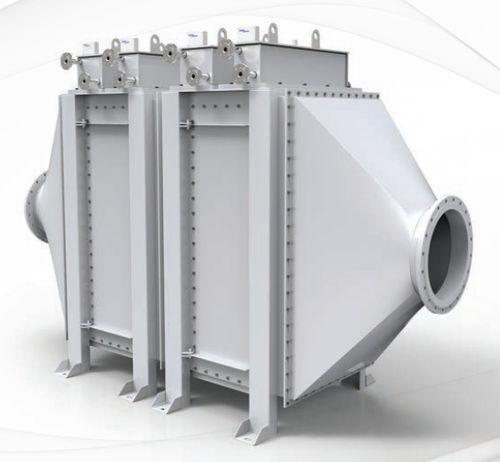

process freezer / tunnel / low-temperature / for food applications

process freezer / tunnel / low-temperature / for food applications

S-16

INO Group

-

Laboratory/process:

process

-

Other characteristics:

tunnel, low-temperature

-

Applications:

for food applications, cooling, crust

-

Temperature:

Min.: -6 °C (21.2 °F)

Max.: -4 °C (24.8 °F)

Unitherm’s patented crust freezing technology optimizes the condition of every log as an in-line process. The ideal condition for Ham and Turkey logs is between -4°C and -6°C on the product’s surface and 1°C at the core. By crust freezing the surface 2 mm deep the blade slices a clean hard edge eliminating folds and tears which improves profitability and productivity from the slicer. Unitherm’s crust freezers are closed systems typically using Freon or Ammonia at -40°C.

Unique to the design of the freezer is a cleaning step to pasteurize the freezer itself. This sterilization step ensures that the logs are not contaminated by particulate during the crusting process.

FLEXIBLE

- Multiple Product Sizes

- Adjustable Time, Temperature, Fan Speed

- Custom Carrier Racks & Machine sizes

PROFITABLE

- Reduced Freeze Time

- Eliminate Folds and Tears

- Increase Slicer Productivity

- Energy Efficiency

CLEANABLE

- Pathogen Free Sterilization

- CIP

- Easy Access Doors

- AMI Sanitary Design Approved

EFFICIENT

- Closed System (Freon, Ammonia or CO2)

- Minimal Footprint

- High Velocity Air

- Linear or Spiral Applications Available

RELIABLE

- Fully-Welded

- 304, 14-guage Construction

- Stainless Steel Belt, Drives, Shafts, Motors

- American Made, CE Approved, UL Listed

- Ethernet Support