-

Type:

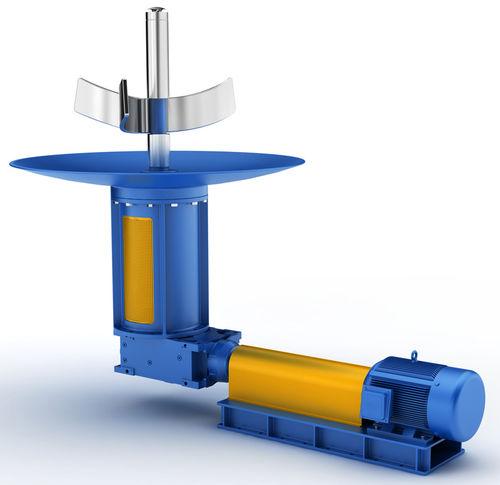

paddle

-

Other characteristics:

stainless steel, vertical

-

Associated function:

disperser, 2D code reader

High Viscosity Mixers

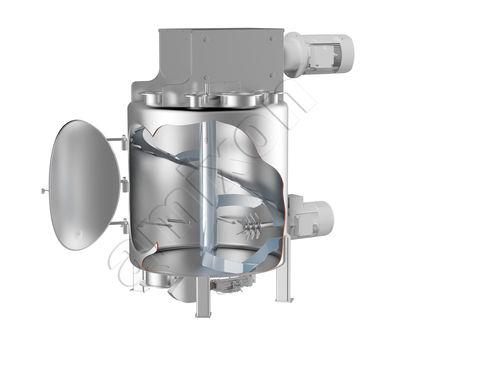

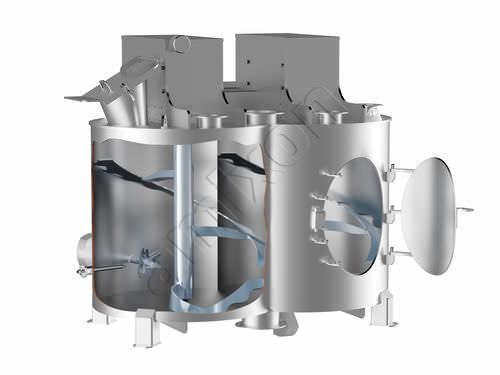

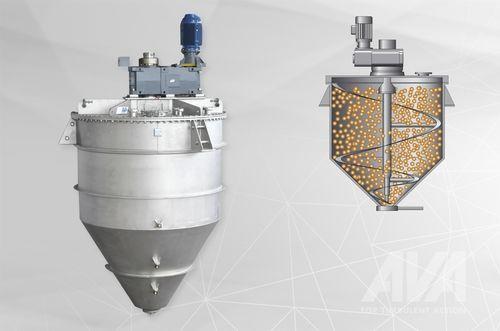

Multi Shaft high viscosity mixers are available in Offset Mount (separate mixer drives) and Concentric Mount (both mixer drives mounted in center) arrangements. Typically a Dual Shaft high viscosity Agitator or Triple Shaft Mixer is used in blending applications where more than one mixing action is needed. The most common is the anchor slow speed paddle (often a Teflon wall scraper anchor) and a turbine agitator or high shear mixer. Multi agitator mix tanks offer great blending capability for higher viscosity mixtures and allow processors to handle a wider variety of products.

For high viscosity blending applications, multiple flow impellers are arranged to assure complete product movement, very uniform heating and cooling with jacketed vessels, and mixing with no dead zones.

Typical operating speeds of multi agitators are:

Anchor Wall Scraper: 5-30 RPM

Top Entry Turbine Agitator: 50-350 RPM

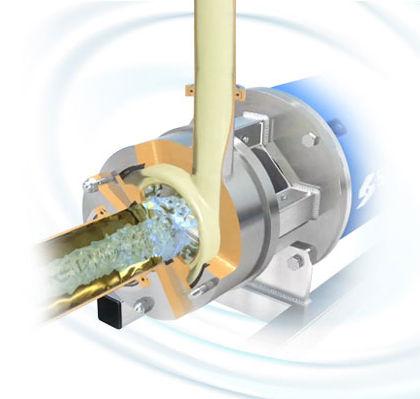

High Shear Mixer Disperser: 1750 RPM / 3600 RPM

Bottom Entry High Shear Mixer Homogenizer: 1750 RPM / 3600 RPM

paddle mixer / stainless steel / vertical / disperser

paddle mixer / stainless steel / vertical / disperser