-

Drive type:

electro-hydraulic

-

Other characteristics:

cutting

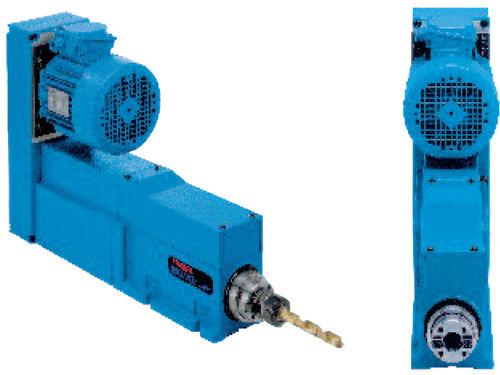

This machining unit, made from standardized

components with hydraulic feed

control, can generate high-performance

results. Even tough metal cutting and

tooling problems can be resolved with

this combination of a quill feed design

and a hydraulic feed control system.

– Basic design advantages are the same

as for the BEM 20 type.

– A technical design concept which allows

the application of high-performance

electric motors for increased torque

requirements, if necessary.

– Spindle speeds up to 10 000 rpm with

frequency converter (optional).

– Chrome plated quill and honed spindle

housing for extended spindle life.

– Exceptional design rigidity for the application

of multiple spindle life.

– Rapid advance and feed motion are controlled

externally.

– Suitable for carbide tooling applications.

– BEM 25 H with HSK spindle includes an

integrated 4-point clamping set form C,

for manual tool clamping.

electro-hydraulic drilling unit / cutting

electro-hydraulic drilling unit / cutting