-

Options:

lubricant quality

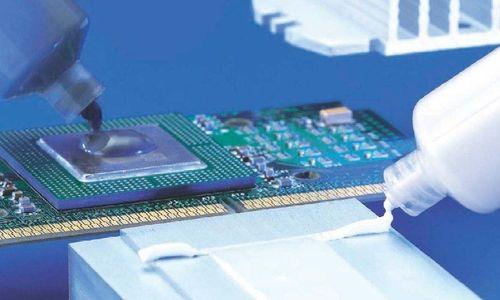

CACTUS is a breakthrough sensing instrument that monitors in real-time the ageing of oils in service by measuring fluid’s viscosity, density, relative humidity (water activity) and temperature. CACTUS can either be installed online, embedded onto larger systems or used in a lab for quality control purposes. The device becomes a decision tool for maintenance teams, ultimately avoiding critical failures due to poor lubrication. On the other hand, it helps bringing maintenance costs at its lowest by detecting the correct moment for a lube change.

CACTUS EMBEDDED CONDITION MONITORING : 70% of failures happening to rotating machines is found to be as a result of poor lubrication, oil contamination or uncontrolled ageing. This considered, ensuring that lubricant meets best quality standards is of paramount importance. CACTUS monitors the fundamental changes occurring to oils. CACTUS prevents you from experiencing the uneasy financial and operational consequences of catastrophic failures.

MESOSCALE TECHNOLOGY : The patented MESOSCALE all metal construction provides unrivalled ruggedness, sensitivity, integrity and dynamic response to changes in the lubricant oil composition.

TYPICAL APPLICATIONS

CACTUS performs continuous hydraulic and lubricating oils quality analysis for the condition monitoring of machineries. CACTUS detects the very first signs of oil ageing in its earliest stage.

lubricant quality remote monitoring system

lubricant quality remote monitoring system