-

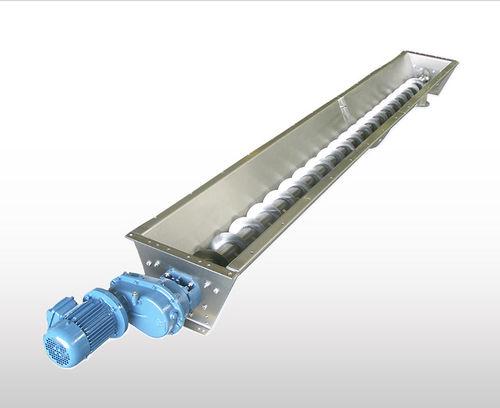

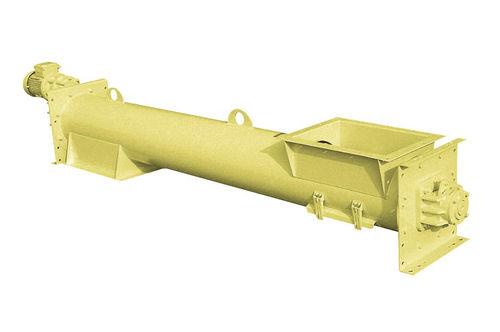

Type:

grizzly, vibrating

-

Operational mode:

linear

-

Product applications:

for hoppers

A Wide range of Grizzly Screen Feeders are available to suit almost any scalping operation particularly for handling difficult and aggressive materials.

● Capacities up to 1500 tonnes per hour.

● Handling single particle lumps up to 2.5 m edge length

● To withstand high impact loads when installed directly under dump hopper.

● Sizes up to 3.5 m wide and 8.5 long - larger sizes available on request.

Vibrating screen’s operating principle

In screen grading, the material is separated mechanically on screen plates. Rolling bearings in vibrating screens are stressed by high, mostly shock-type loads. Moreover, the bearings, while rotating about their own axis, perform a circular, elliptical or linear vibrating motion. This results in high radial accelerations which additionally stress the bearings, and especially the cages, considerably. The operating speeds are usually very high. As a result, the bearing temperatures are up to 20 to 30 degrees Kelvin higher than in normal applications. In addition, considerable misalignments between the bearing locations and considerable shaft deflections have to be accommodated.

grizzly feeder / vibrating / linear / for hoppers

grizzly feeder / vibrating / linear / for hoppers