-

Other characteristics:

electric

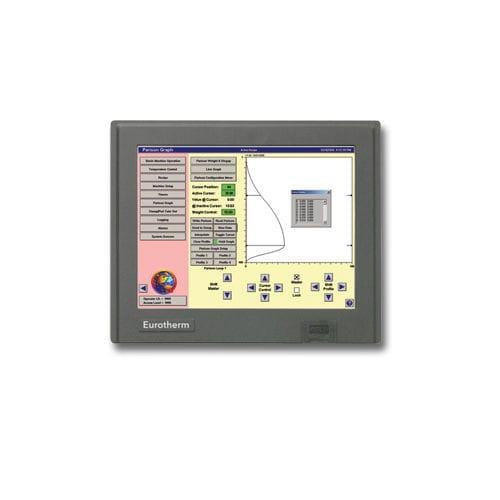

Dragflow has developed a line of advanced electric control panels that allow real time and historical monitoring of pumps and dredging equipment.

With our control panel remote engineers can control working operations and inspect downtime causes. Possibility to access to the history of working parametes and allow the own of Dragflow equipment to have a complete overview of the status of its equipment.

Basic Version

Reactor Start, Soft Start, Inverter Control Panel

Top Class Components: Rockwell - Exor - Mitsubishi

Ammeter and Voltmeter

Input: 380V-50Hz or 460-575V-60Hz

Desing and buit by Dragflow

High Quality Enclosure

Emergency stop button

CE - CSA and UL Certified Control Panel

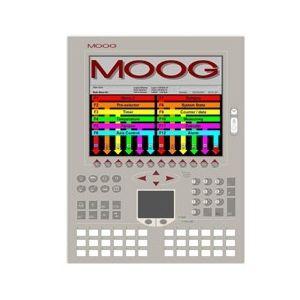

Plus Version

High-performance internal touchscreen HMIs

Display 4,3 TFT 16:9 for setting and immediate parameters inspection

USB/SD card slot for storage of working parameters

Excel Data Analysis on working parameters history

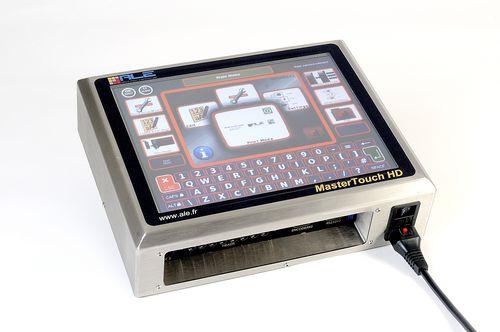

Full-Control Version

High-performance touchscreen HMIs - Ideal for marine and mining applications

Display 7 TFT 16:9 for setting and immediate parameters inspection

USB and SD storage of working parameters

Excel data analysis to inspect equipment working condition and history

Worldwide 3G/3G+ networks and Ethernet connection for real-time remote monitoring and control

Full Internet access to machine parametes and history

Advanced control Panel are available also for Dredge and Power Pack control and monitoring. Besides remote monitoring it is also possible to have wireless remote control unit to run and mofidy working parameters by a remote operator.

electric pump controller

electric pump controller