thermal regulator with carbon dioxide circulation / with touchscreen / for injection molding machines

thermal regulator with carbon dioxide circulation / with touchscreen / for injection molding machines

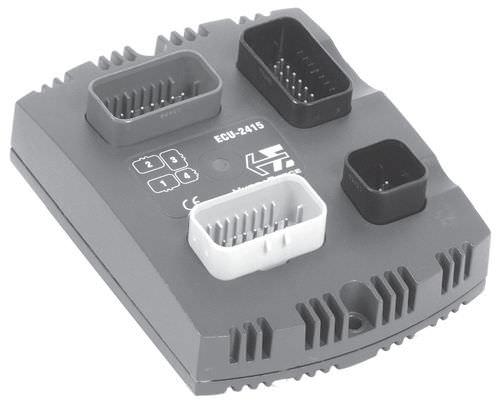

integrat vario gt

INO Group

-

Type:

with carbon dioxide circulation

-

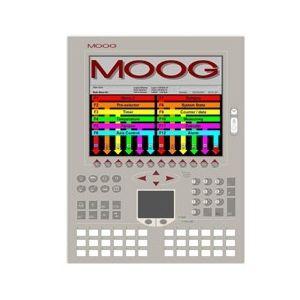

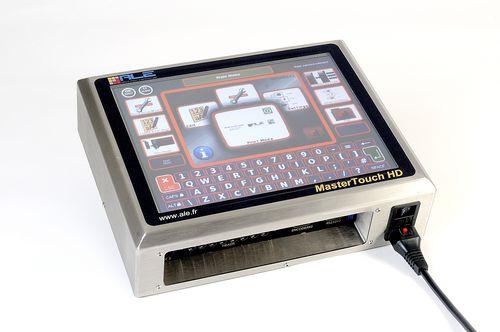

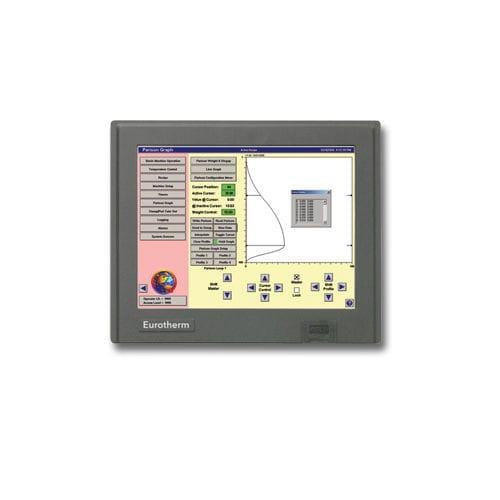

Display:

with touchscreen

-

Use:

for injection molding machines

-

Maximum temperature:

-76 °C (-104.8 °F)

Brand-new perspectives and possibilities are offered by the dynamic temperature control with CO2. This new and environmentfriendly procedure really provides a solution for heating and cooling of complex and thinwalled

moulded parts. By using gaseous media for heating and cooling processes, soiled cooling channels are now a thing of the past. Basically it is true that gaseous media have the disadvantage to be bad heat carriers.

This applies at least to air that is only used for cooling processes under special circumstances. But in contrast, if the opportunities of CO2 are exhausted properly, it offers an interesting alternative to conventional water temperature control.

Cooling with CO2 is suffi ciently tested and well-known. The high enthalpy of evaporation of the injected fluid accompanied by a temperature of -76°C offers an extremely effi cient heat transfer. As far as cooling of long and thin cores or of narrow bars is concerned, cooling with CO2 has already been applied with great success for many years. Nevertheless, the new feature is that heating is also possible with gaseous CO2. In the vario gt CO2 is compressed to a suitable pressure and heated close to the mould cavity.