Humidity measurement in cheese ripening cellars (93%RH)

The challenge

The storage of the individual ripening process is a fundamental part of cheese production. Climatic conditions such as temperature and relative humidity are among the most important parameters, which are responsible for taste and appearance of the cheese wheels.

Depending on the cheese type, capacitive relative humidity sensors manifest large drift effects after a few days or weeks. Due to saturation influence caused by high air humidity, such sensor types are subject to slow reaction or no reaction at all and therefore they cannot be relied upon to detect the true values.

The air contamination by ammonia, for example, which is outgassing during the ripening process, can further influence the measuring element negatively.

Capacitive sensors of various manufacturers and design as well as polymer-thread sensors show the same behaviour.

Best alternative & solution

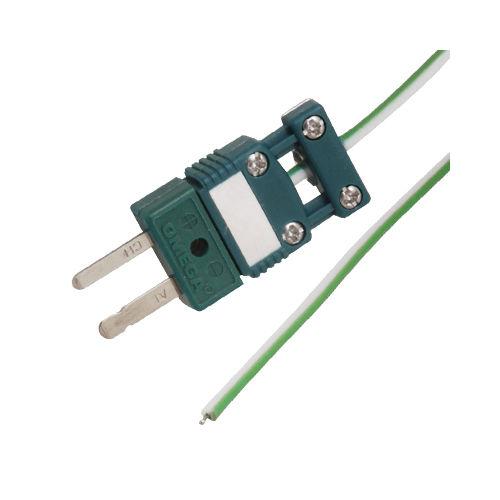

In the ripening cellar of a large Swiss cheese producer, Novasina probes type nSens-HT were installed for 3 months to monitor the climatic conditions. These are based on the resistive-electrolytic measurement principle, which, contrary to other measurement principles, is not subject to the saturation problem and allows fast and reliable response times.

There were no measurement deviations during the observation time with all Novasina probes. All 4 probes show the same values. Reference measurements confirm the values.

An accurate analysis of the Novasina sensors after the 3 months did not show any measurement deviations or traces of corrosion.

humidity probe

humidity probe