-

Method:

PECVD, PVD

Most important Features:

Combined PVD & PECVD process - to deposit very smooth coatings

Special Si containing gas line - controlled by additional Mass Flow Controller

Silicon increases heat resistance

Silicon decreases internal stress of the coating

Silicon improves adhesion -> thick DLC coatings are possible

BIAS supply 350 kHz - to enable deposition of non-conductive layers.

Special heaters with dust filter

grids in front of the heaters

to avoid contamination of the substrates by dust released from the heaters

VIRTUAL SHUTTER® to clean the target to the back before deposition.

Mechanical TUBE SHUTTERS® to protect targets

against contamination by acetylene

against being coated when idle

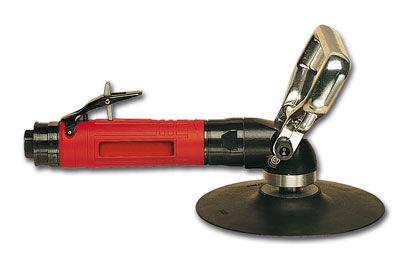

PECVD deposition machine / PVD

PECVD deposition machine / PVD