-

Number of axes:

6-axis

-

Other characteristics:

surface measurement

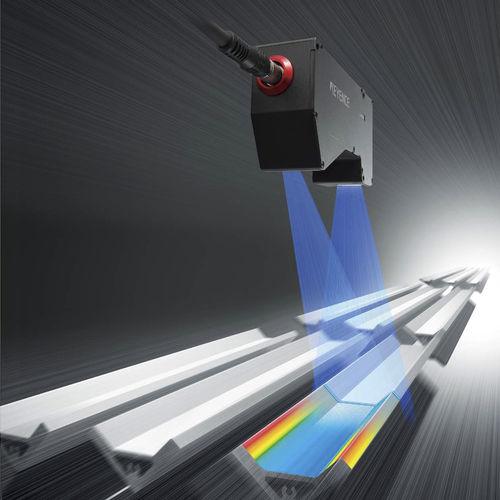

Create modern production strategies with the new collaborative robot systems by Alicona

Avoiding sharp edges on turbine disks

A new robot measuring system by Alicona allows for the quality assurance of round, heavy components with a weight up to 120kg. One application is the production-integrated measurement of turbine disks. To ensure the safety of aircraft sharp edges need to be avoided. The Alicona robot measuring solution helps users to detect chipping along the edge and to verify minimum radii. Other applications include the quality assurance of circular saw blades or grinding wheels.

Measuring tools with a long shaft

A further new collaborative system enables for the automated cutting edge measurement of drills and cutters, which have a shaft of up to 1 m length. The new measurement solution allows for the verification of cutting edge geometries, roughness and wear measurement and the detection of edge chipping. The corresponding test set-up is a 9-axis solution: The 6 axis robot is complemented by the 3D optical measurement sensor, the rotational axis of HSK interface and a variable stroke axis. The user determines the positioning of his tool in height and, in combination with the rotation axis, creates the best possible access for measurement.

6-axis 3D measuring arm / surface measurement

6-axis 3D measuring arm / surface measurement