-

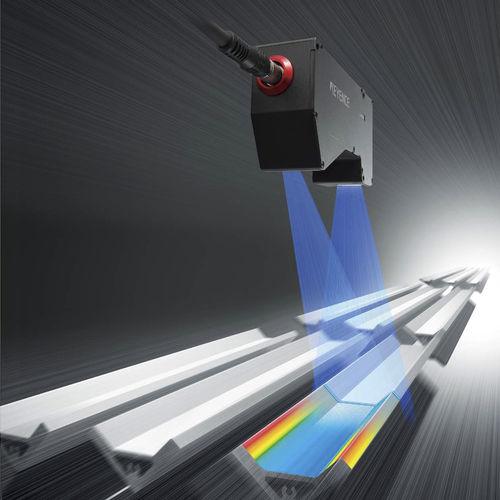

Technology:

optical

-

Other characteristics:

CNC, non-contact

Economical Non-Contact Optical Vision Measuring System (SV-3020 CNC)

Non-Contact Optical Vision Measuring System (SV-3020 CNC) is widely used in the measuring machinery, electronics, mold, injection molding, metal, rubber, low voltage electrical, magnetic materials, precision metal, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, PCs, LCD, circuit board, PCB, automotive, medical equipment, clocks, screws, springs, instruments, gears, cams, threads, wire and cable, tools, bearings, screen, net plate (steel mesh, SMT template), and others.

SV series video measuring system is a kind of very economical vision system machine, but its performance is also very good for the measuring and inspecting.

Specification

Model SV-3020 CNC

Travel-X.Y axis(mm) 300*200

Travel-Z axis(mm) 200

Feed mechanism Manual

X,Y-axis accuracy(μm) 3+L/200 L=measuring length(mm)

Repeatability(mm) 0.003

Stage size(mm): 456*356

Stage load capacity(kg) 15

Illumination Contour illumination:LED lamp; Surface illumination:LED ring light

Dimesion(mm) 680*600*1030

Power supply 100V-120V/200V-240V AC, 50/60Hz

Net weight 160

Vision system CCD 1/3'' High resolution color CCD camera

Zoom lens 0.7x-4.5x

Magnification Video total magnification:30X-190X, Field of view: 8.1-1.3mm

Working distance 90mm

Light source Surface light:LED,contour light:LED, light adjustable

Digital resolution 0.001mm

Standard Delivery

Main unit, Metrology 2D measuring software, USB encoder interface

Continuous zoom lens 0.7x-4.5x, magnification: 30x-190x

1/3'' High resolution color CCD camera

LED cold Light sources for surface and contour illumination

Anti-dust cover

English user manual

optical measuring machine / CNC / non-contact

optical measuring machine / CNC / non-contact