dimensional inspection system with infrared optical sensors / for harsh environments / non-contact

dimensional inspection system with infrared optical sensors / for harsh environments / non-contact

VIGIPROD®

INO Group

-

Options:

with infrared optical sensors, for harsh environments, non-contact

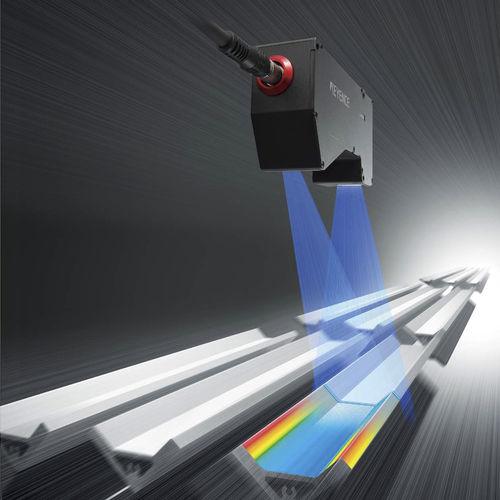

VIGIPROD is a no-contact measuring system partucularly suited for applications in harsh environments.

It enables one to very accurately measure fixed or moving parts on high-speed production lines. Measurements are performed using infrared optical sensors.

The system is fully automated and very easy to operate.

VIGIPROD 2 is the successor of VIGIPROD 1 that had worked to the full satisfaction of the industry all over the world.

PRIMARY FEATURES OF THE VIGIPROD:

• Uses infrared optical sensors (Transmitter/Receiver).

• Power supply: 24V DC.

• Fully automated and user-friendly system (PLC, Graphic Color Touch Screen).

• Up to 8 diferrent measurements on the same part.

• Measuring range: 0.5 to 2mm per sensor.

• Unlimited number of calculation.

• Inspection speed: up to 20 pieces/second.

• Measuring accuracy: +/- 0.5 μm, repeatability: 0.1 μm.

• Inspection of fixed or moving parts.

• Instant or continuous measurement.

• Fitted with sensors self-test system.

• Up to 127 inspection programs.

• Quick change of program when needed.

• Backup to USB flash drive.

• Communication via Ethernet and RS 422 (MODBUS TCP).

• I/O for process control and/or interface with the PLC.

• HIM can be transfered to PC.

• Suited to applications in harsh environments.