-

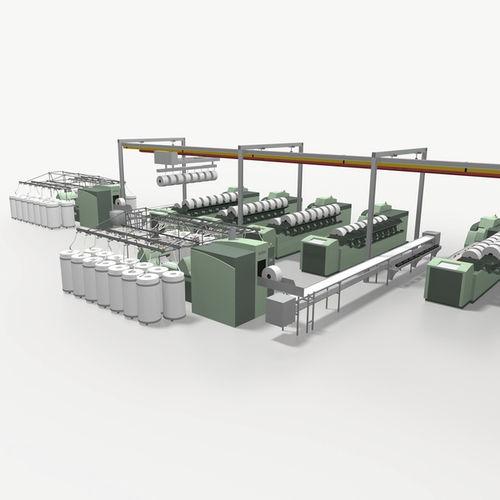

Applications:

for cotton, process

Top technology in a unique application

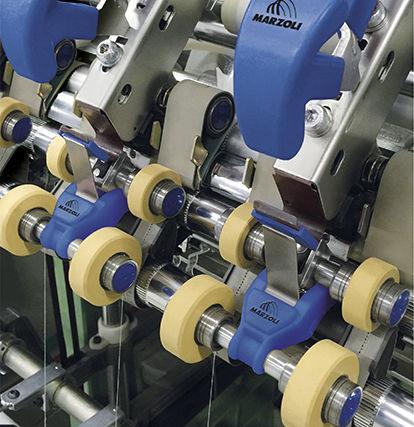

USTER® INTELLIGIN combines world-class HVI® color and trash sensors with patented moisture measuring to create a unique system for raw cotton processing.

The sensors work online, at measuring stations along the gin, to analyze trash content, color grade and moisture. The gin operator can then customize settings to suit the incoming seed cotton. Drying temperatures, pre-cleaning equipment and lint cleaners can all be adjusted for optimum ginning.

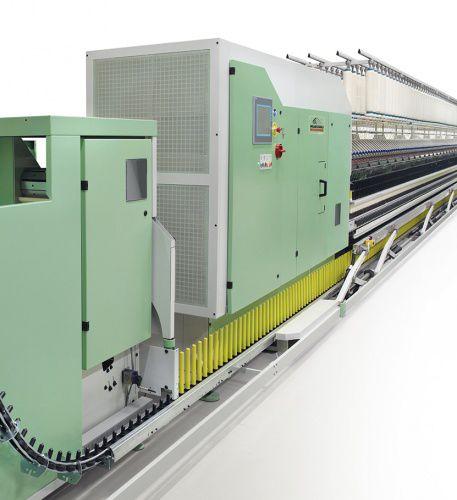

Tough and strong for a rugged environment

USTER® INTELLIGIN is built to stand up to the tough environment of a gin. Heavy dust particles and lint are the norm. So, all critical sensor components are protected in a sealed enclosure at the sampling stations. This ensures they provide reliable data, non-stop, unaffected by external conditions.

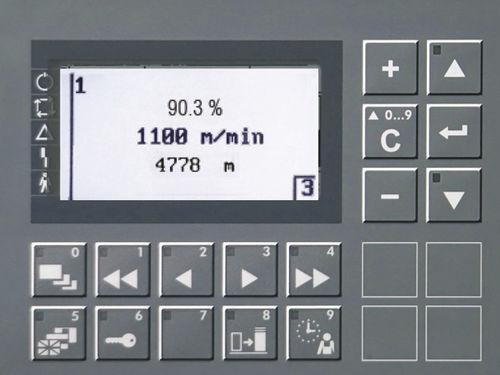

Fast and simple to use

USTER® INTELLIGIN tests up to six samples from every bale arriving at the gin. Test data is then relayed to a central console, which presents critical data and applies preset alarm limits. It all happens fast, in real time – so immediate decisions can be made to preserve the quality of each batch of cotton.

Maximum yield or optimized quality

USTER® INTELLIGIN provides ultimate control and choice for the grower and spinner. Naturally, the grower wants the highest-possible yield from his crop – while the spinner needs top quality fiber. USTER® INTELLIGIN means the ginner can strike the ideal balance, based on intelligent gin settings. High yield, best fiber quality, or a blend between the two...it depends on the grower’s price schedule. And the system also reduces ginning costs through process and warehouse efficiencies.

cotton monitoring system / process

cotton monitoring system / process