-

Type:

ring

-

Other characteristics:

for worsted yarn

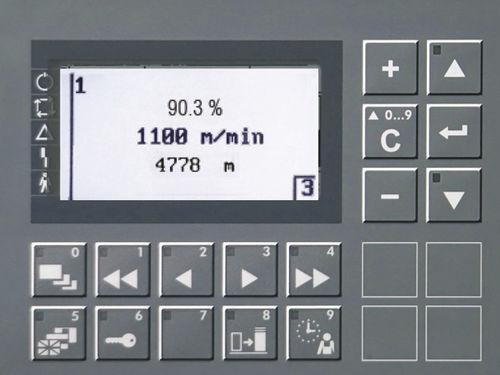

All important parameters in a single report

Every parameter influencing machine performance is included in the intuitive bobbin build-up report. Clear visuals point to exact reasons for end-breaks, making corrective actions easier.

Ultimate optimization with the Total Testing Center

USTER® SENTINEL is ready for connection to the Total Testing Center of the USTER® TESTER 6. Here, integration of data from all spinning processes with USTER® SENTINEL information on end-breaks, ringframe speeds and the condition of machine parts creates the ultimate quality optimization package.

Personnel management

USTER® SENTINEL makes operator workloads easier, as single-spindle monitoring reduces the need for patrols. Its reports also contain valuable information to improve assignment of personnel duties in the ring spinning department.

Energy monitoring

Rising costs mean spinning mills need to monitor power consumption carefully, especially in ring spinning – the most energy-intensive process in the mill. USTER® SENTINEL provides detailed information on energy use, including comparing the consumption per kilo of yarn between different machines.

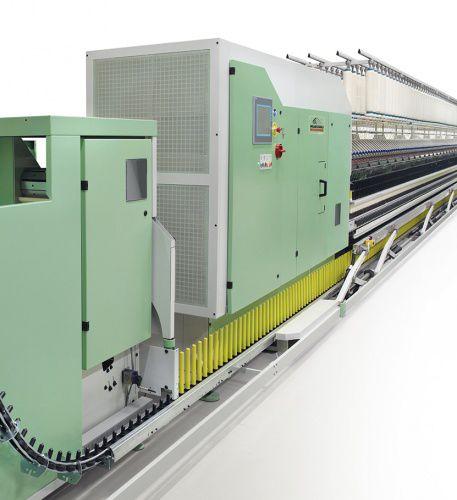

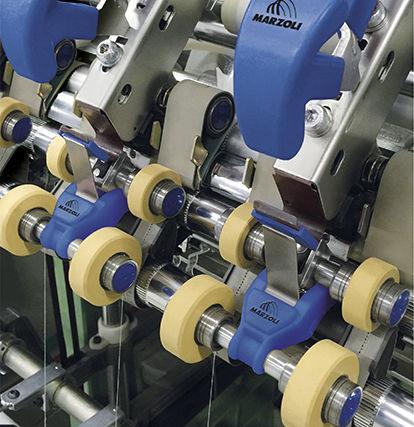

USTER® ROVING STOP

USTER® ROVING STOP minimizes pneumafil waste and achieves higher yield from roving to yarn. Lapping at front rollers is eliminated, avoiding potential damage. USTER® ROVING STOP operates without touching the back rollers, which also prevents damage to machine parts.

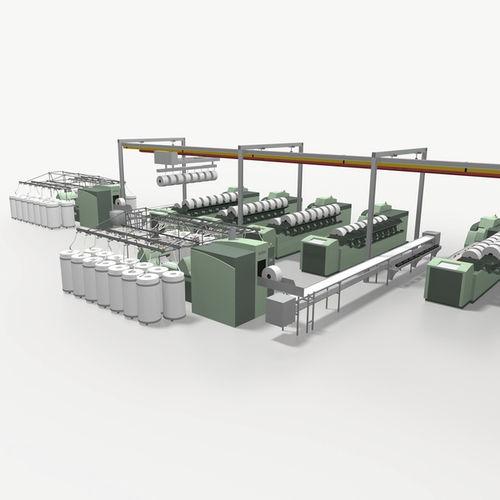

ring spinning machine / for worsted yarn

ring spinning machine / for worsted yarn